Potomac Photonics is passionate about microholes. We have some of the most advanced hole drilling capabilities and are continually developing new processes to drill holes as small as 1 micron. Our engineers will work closely with you to fully understand the requirements for your microholes (e.g. materials, part thickness, desired feature geometries, taper, etc.) and recommend a process that will satisfy both your prototyping and production needs.

Examples of materials that Potomac has microdrilled include:

Microhole Drilling in Polymers (Plastics)

- Polyimide (Kapton)

- Polycarbonate

- PEEK

- LDPE

- HDPE

- Silicone

- ABS

- Nylon

- BoPET (Mylar)

- and more.

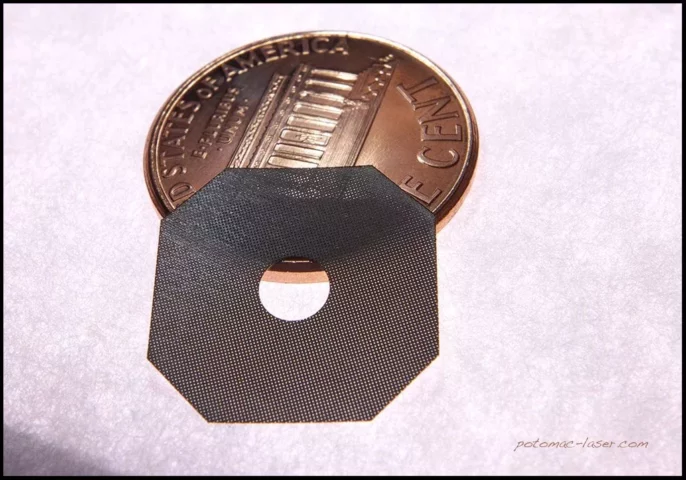

Microhole Drilling in Metals

- Stainless Steel

- Copper

- Nitinol

- Brass

- Tantalum

- Titanium

- Aluminum

- and more.

In addition to microhole drilling polymers and metals, Potomac can drill

Ceramic, Silicon Wafers, Glass and more.

Microhole Drilling Experience

Experience

Our Microhole Drilling experience includes (but is not limited to):

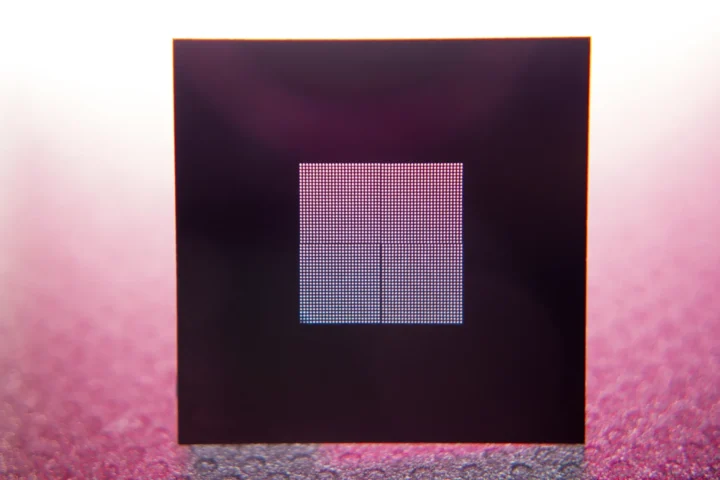

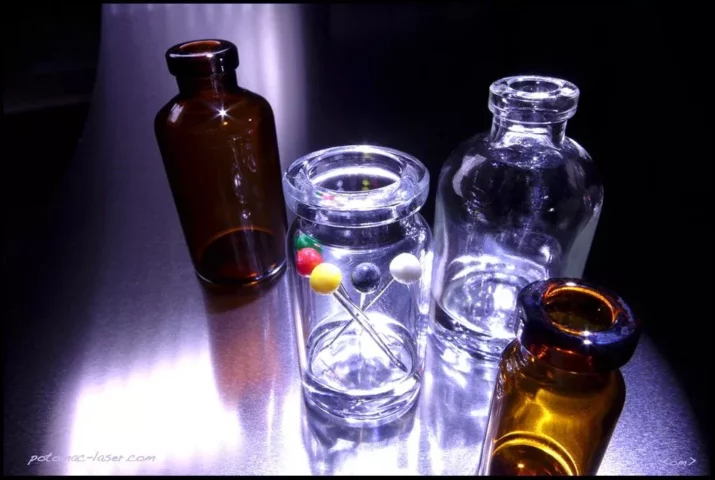

We specialize in advanced laser drilling technology for container closure integrity (CCIT) leak testing. Our precision laser systems create micro holes from 2µm to 100µm in materials like glass, plastic, and metals, ensuring accurate and reliable CCIT. Our ISO 13485:2016 certified processes guarantee high quality and rapid turnaround times, often completing projects within a week. Our versatile capabilities allow us to handle various package types and materials, providing flexible and efficient testing solutions to meet your needs.

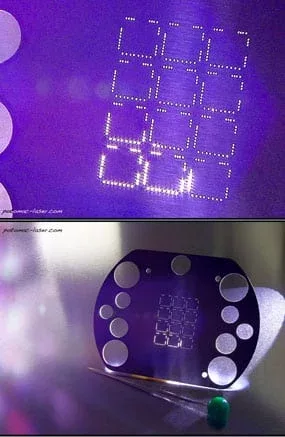

Our advanced laser technology at Potomac Photonics drills micro-holes as small as 2 microns with tight positional tolerances for probe card applications in materials like silicon nitride, polyimide, ultem, and others. We provide comprehensive solutions, addressing both micro-hole needs and larger hole requirements for probe card assembly and orientation.

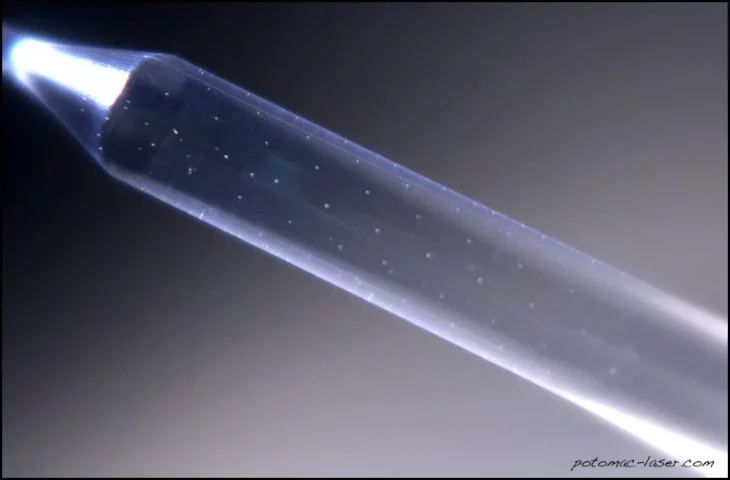

Catheter Microhole Drilling – Extremely tight tolerances on hole diameter and position are critical for optical fiber connectors and alignment devices. Utilizing the latest laser technology and high precision Aerotech stages that are calibrated to a NIST traceable standard, we are able to meet or exceed the requirements of some of the most challenging fiber optic applications. In addition, we continue to improve our capabilities to drill thicker materials that are often required for placement of fiber optics with diameters of 125 microns and greater.

- Calibrated Flow Holes

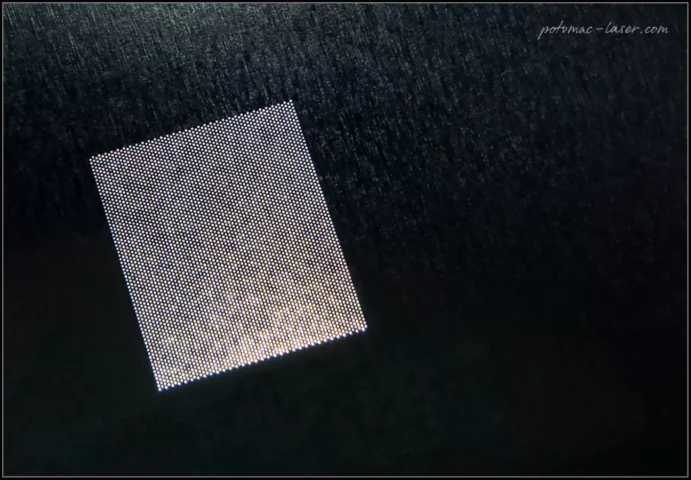

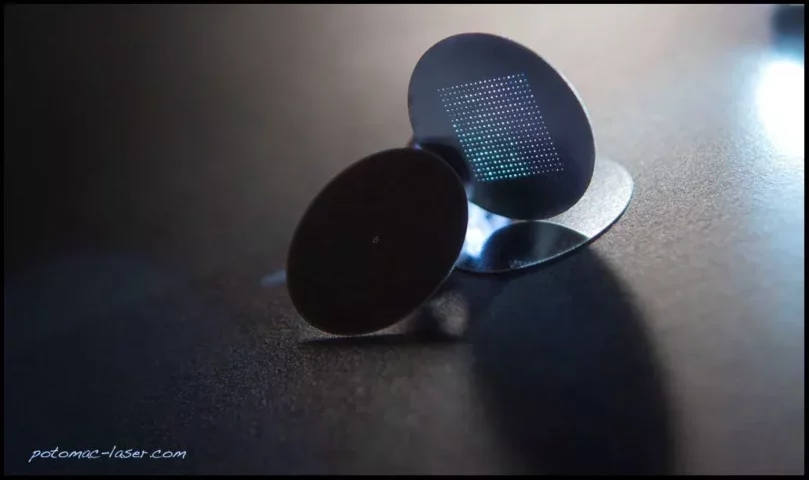

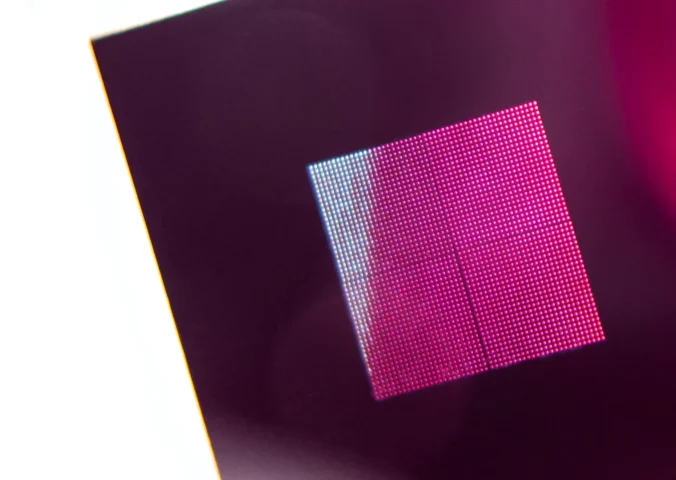

- Filters

- Fuel Cells

- Inhalers

- Nebulizers

- Ink Jet Nozzles

- Fuel Injection

- Pinholes for Photographic Applications

- Optical Apertures, and many more.

Critical items to consider when planning a hole drilling project include the thickness of the material, the shape, edge quality, diameter and taper of the hole as well as the desired center-to-center pitch of the holes.

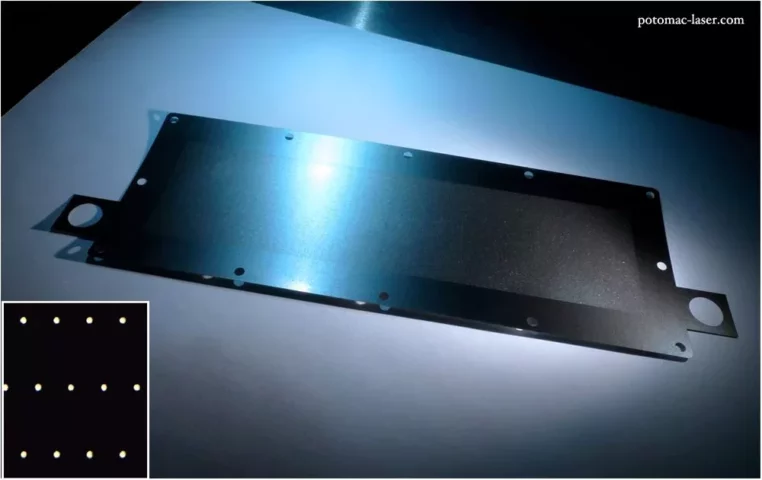

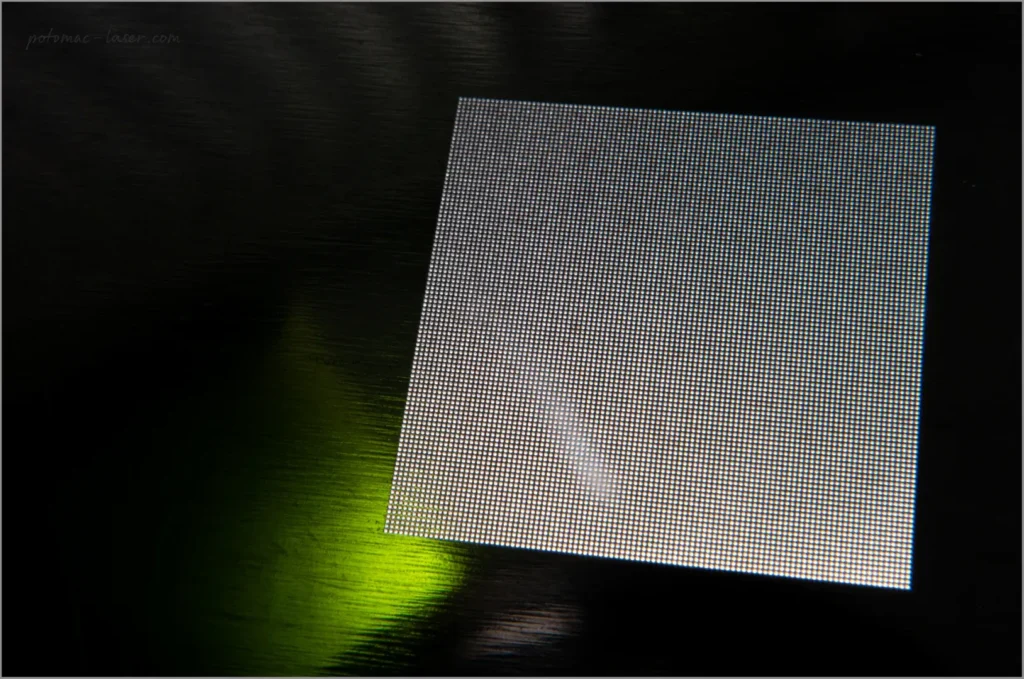

Potomac is continually developing and adding new hole drilling processes to our facility. Our broad range of technologies includes the capability to drill angled and shaped holes on multi-axis drilling systems. In addition, we can drill material thicknesses from very thin films to several mm’s on high speed set-ups that drill 1,000’s of holes quickly and repeatably.

Depending on the material and specifications, Potomac will choose the appropriate tool to drill the holes. For example, if the substrate is a transparent polymer, UV laser sources are often the best choice. However, if the material is a metal or ceramic, IR lasers are used. Potomac also has micro-cnc systems for applications that require larger features and no taper.