3D printing is an additive manufacturing process that builds solid objects by adding material layer by layer, in contrast to subtractive methods like CNC or laser machining, which remove material to shape a part. Since 3D printing is such a different type of process, the technology opens new doors to making things.

There are several different types of 3D printing, from the extrusion used in personal desktop printers to stereolithography that was invented by Chuck Hull, the founder of 3D Systems Corporation, in 1983.

Like all digital fabrication methods, 3D printing relies on a Computer-Aided Design (CAD) file to guide the process. Just as a CAD file instructs a CNC machine where to cut, it directs a 3D printer on where to deposit material.

Digitally driven additive manufacturing processes are ideally suited to the following scenarios:

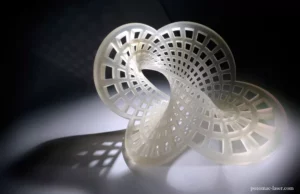

- Creating Complex Geometries

Because parts are built from the ground up, so to speak, complex geometries that are impossible with traditional manufacturing can be easily created. Internal structures such as lattices are now possible, bringing advantages in weight reduction, lower material costs, and aesthetic beauty. These types of parts are driving 3D printing applications in the aerospace and automotive industries, where weight reduction translates to fuel consumption savings.

- Mass Customization

Designs from a CAD file can be quickly and easily modified, meaning that each part can be customized to the end user. This type of mass customization is driving the medical device market, which is currently the largest user of 3D printers. Prosthetics, orthotics, hearing aids, and surgical guides are just a few examples of how 3D printing can create personalized solutions that are tailored to the individual. This customized approach helps reduce the risk of infection caused by poor fit, shortens surgical times, and can even boost self-esteem.

- Rapid Prototyping

Although 3D printing has moved to the production mainstream, it is still a great tool for rapid prototyping. Parts can be created overnight, drastically improving turnaround time over traditional manufacturing methods. Plus, no expensive mold or mask is required, reducing costs. Prototypes made by 3D printing technologies also allow designers and engineers to test new products in an iterative process, ensuring optimal success!

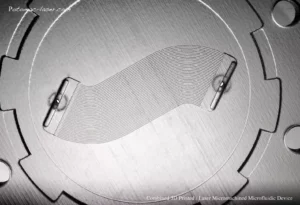

Integrating 3D Printing with Other Digital Fabrication Tools

At Potomac, we have a full range of digital fabrication tools and can always choose the right tool for the job. We often combine 3D printing with other advanced technologies, such as micro CNC and laser micromachining, to achieve optimal results. The ability to choose the right tool for every task is a testament to our decades of expertise in the field.

Additionally, our contract services seamlessly guide you from prototype to production. When you’re ready to bring production in-house, we will have developed the exact process for your 3D Systems production printer.

Contract Services

Potomac has worked in digital fabrication for over 30 years and can take your project from prototype to production. In-house, we can help you define the process for your toughest manufacturing jobs and work iteratively with you every step of the way.

To get started, just send us a drawing!

Purchase 3D Systems Equipment

As an authorized re-seller of 3D Systems Corporation, we are your trusted partner for bringing 3D printing in-house. With extensive experience using 3D Systems machines in our own facility, we can guide you in selecting the perfect 3D printer for your specific needs.

Contact us today for equipment specifications and to discuss your application, whether it’s for production, professional use, or education.

Applications

- Rapid Prototyping

Although 3D printing is now being used in a wide range of production applications, its original application as a rapid prototyping tool is still important in many industries including medical devices, aerospace, automotive, consumer products, sensors, microfluidics, and biotech.

3D Systems offers a comprehensive range of 3D printers for rapid prototyping, from the compact CubeX desktop model with a build area the size of a basketball and the option for up to three print heads, to larger, more advanced professional models. Whatever your budget or application requirements, there’s a 3D printer that perfectly suits your needs.

Contact Potomac to learn more about how 3D Printing can speed up your design process while keeping costs affordable.

Dental

It’s a whole new 3D world in dentistry! Dental labs are turning to 3D printing for improved work flow and higher accuracy. The results save dentists time fitting the prostheses with fewer bite problems for the patient. Turnaround times are also quicker, and all at an economical cost with good ROI.

- Small Batch, Tabletop 3D Printer

The ProJet 1200 3D Printer is an economical tool for making accurate, ready-to-use casting patterns at about 50 cents per part. This inexpensive parts-cost, combined with the low machine purchase price of just $4,900 and built-in post-processing, brings 3D printing into the dental lab with a high ROI.

The ProJet 1200 is comparable in size to a coffee maker, with an 8 x 8 base and a height of 13 inches, with both LAN and USB connectivity so everyone in the office can use it. Convenient all-in-one material cartridges are quick and easy to use. The built-in UV curing station assures safe handling of the parts and locks in their mechanical properties.

And quality is second to none. The ProJet 1200 uses a micro SLA process. This type of 3D printing is highly sophisticated with the beautiful surface finish usually associated with more expensive, high-end machines. With a 30-micron layer thickness, there is good accuracy for prostheses to have the fit you need for a perfect bite.

According to Chuck Stapleton at Sun Dental Labs in Clearwater, Florida, “the batch size is perfect to keep a production line moving. We can produce what we need in between 45 minutes and 1.5 hours, that fits better into our flow of manufacturing than bigger batch sizes. Even better, the small size and low price of the ProJet 1200 gives us redundancy, which is key in on-time delivery to our customers. While we still use our ProJet 3000 series machines for casts, the ProJet 1200 is perfect for printing wax.”

- Direct Metal Production

3D Systems is one of the few companies that manufactures 3D printers capable of printing metal parts. They have specifically optimized the Direct Metal Sintering (DMS) process for the dental industry with their ProX™ 100 Dental System. From supporting certified Ni-free CoCr materials for dental use to specialized software integration, the ProX 100 Dental system is a perfect starting point for clients wishing to quickly manufacture small, complex dental prostheses.

Every 3D Systems’ DMS printer creates chemically pure, fully dense metal and ceramic parts, and they deliver accuracy compatible with EN ISO 2768 (fine) machining tolerances and a repeatability of about 20 microns in all three axes. Materials include stainless steel, tool steel, super alloys, non-ferrous alloys, precious metals and alumina.

To streamline workflow, the ProX 100 Dental features a high-performance software solution for managing the manufacture of fixed and removable dental prostheses. This seamless, intuitive interface quickly guides you from dental file import to the creation of manufacturing files that drive the 3D printer.

Contact our applications specialist today to learn how 3D printing can improve quality and ROI in the dental lab.

Medical Devices

Medical device manufacturing is the single biggest production application of 3D printing, with over 200,000 devices currently being produced each day. 3D printing is uniquely suited to the medical market, where each individual patient is different. This mass customization, the ability to create many devices, each unique to the end user, means a perfect fit for everything from hearing aids to guides for joint replacement surgery to prosthesis. In the dental area, Invisalign orthodontic braces are 3D printed and now molds and even final restorations and prosthesis can be directly made with the additive process.

At Potomac, we have extensive experience helping medical device manufacturers navigate the entire process—from R&D and prototyping to short runs and long-term production. We are therefore well-versed in the unique challenges of FDA approvals and patient trials. We also can steer you toward the best 3D Systems production machine with high throughput, operator ease of use, and substantial ROI.

RELATED TOPICS

3D PRINTING APPLICATIONS

PURCHASE 3D PRINTERS