Adding 3D printing to your traditional manufacturing processes is no small feat. By relying upon Potomac’s extensive expertise in additive manufacturing such as 3D printing, you can quickly and easily make the transition to the next industrial revolution! Potomac can provide:

Product Design Assistance

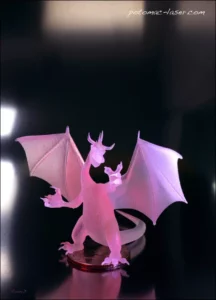

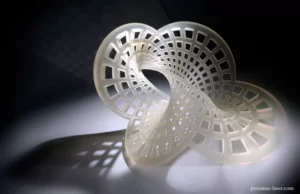

3D printing offers unique capabilities that allow engineers and designers to completely re-think form and function. Instead of merely transferring a subtractive manufacturing CAD file to the printer, we can demonstrate how innovative designs that leverage 3D printing’s ability to create complex geometries can save both time and costs.

Wide Range of Materials

In collaboration with our 3D printing partners, Potomac is capable of micro-3D printing a diverse range of materials, including those that meet FDA bio-compatibility requirements for medical devices. We also offer 3D printing in various plastics such as ABS, PLA, and nylon, as well as acrylics, metals, and ceramics.

Prototyping Services

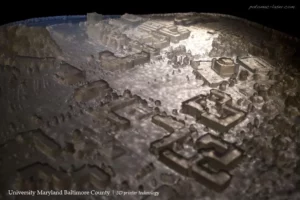

Prototyping is one of the natural applications for 3D printing. The technology produces functional models with quick turnaround that can be tested and then modified with a simple CAD file change. Potomac can work with you to iteratively produce rapid prototypes, getting your new product on the market with efficiency and cost savings, as well as optimal performance characteristics.

Production Manufacturing

3D printing is gaining in speed and quality to rival the best traditional manufacturing processes. Especially for small batch production where designs change or for mass customization, 3D printing shines in the production arena.