Laser Micromachining Metals Laser micromachining of stainless steel, copper, nitinol, tantalum, gold, aluminum and other metal materials. Lasers can be a very efficient and cost-effective manufacturing process to micromachine any type of metal.

- Type of metal being micromachined, reflectivity of material, and feature size desired are the most critical factors in determining the optimal laser source to use.

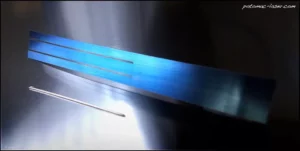

- The laser beam is absorbed into the surface of the material, and the energy of the laser is converted to heat which vaporizes or melts the metal material.

- A gas or fluid assist is often utilized to improve the cut quality, expel molten metal, and minimize the heat-affected zone (HAZ).

- IR lasers are typically the first choice to laser micromachine metals from a quality and cost perspective.

- When features less than 10 microns are required, the UV laser may be a good alternative to the IR, assuming the metal thickness is less than 0.003″.

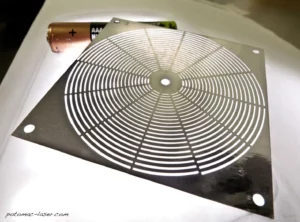

- Intricate and complex features can be cut on both flat and tubular metal substrates utilizing high precision multi-axis motion systems.

- Potomac has experience laser micromachining almost every type of metal material including stainless steel, aluminum, copper, titanium, gold, silver and others. All grades of stainless steel can be laser micromachined including stainless steel 304 and 316.

- Potomac can offer expedited micromachining metals services with lead times as short as 24–48 hours.