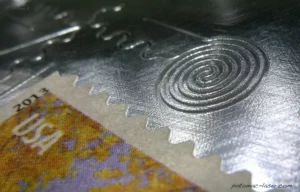

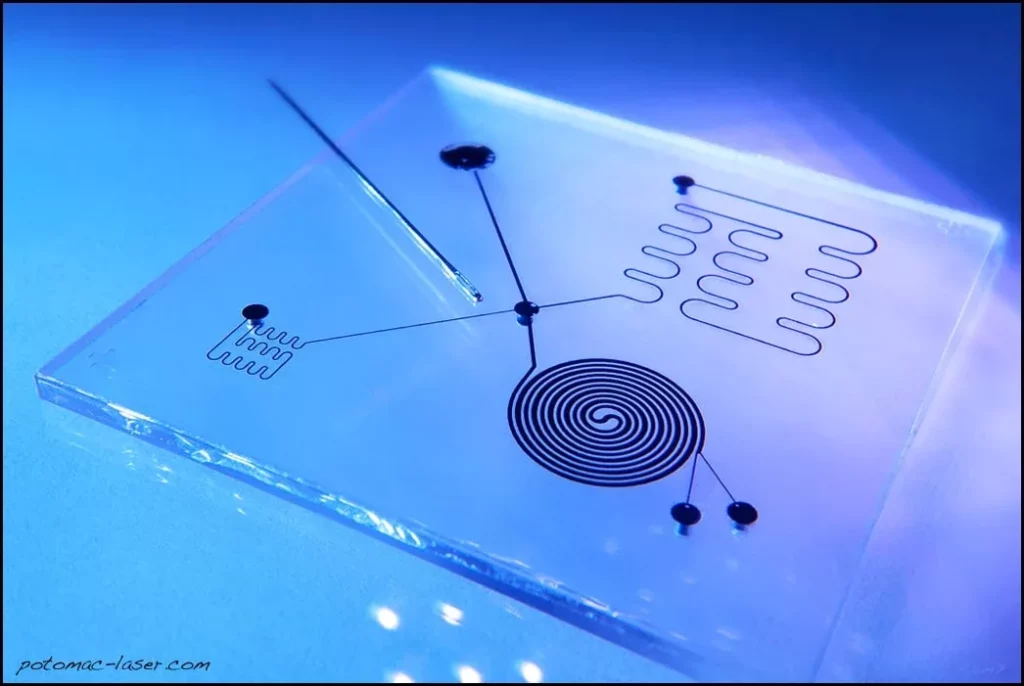

Hot embossing is a very versatile replication method which uses high pressure and elevated temperature to transfer intricate structures from a master mold into a polymer. This process is ideal for a wide range of applications, including microfluidics.

Potomac can produce molds with features as small as a few microns, typically within 24–48 hours of receiving a customer’s drawing. Parts can then be stamped into into a variety of materials, including polystyrene, cyclic olefin copolymers (COC), PMMA, polyethylene, and more.

Advantages of the process—for microfluidics and other applications—include the ability to achieve very clean and precise features quickly and cost-effectively in materials that often cannot be machined utilizing other technologies.

In addition to hot embossing, Potomac also offers services for hole drilling, bonding of cover layers, and integration of conductive lines and sensors to the devices.

Individual process steps that Potomac offers to fabricate a fully functional microfluidic device include:

- Fabricate mold of microfluidic device for hot embossing process.

- Hot emboss microfluidic part in polymer material such as COC, polystyrene, PMMA, and more

- Drill holes in microfluidic device and cut the part to size

- Align and bond cover to microfluidic device

- Inspect and test part for functionality

Potomac Photonics breaks the mold by offering the fastest, most cost-effective path toward producing your microfluidic devices.