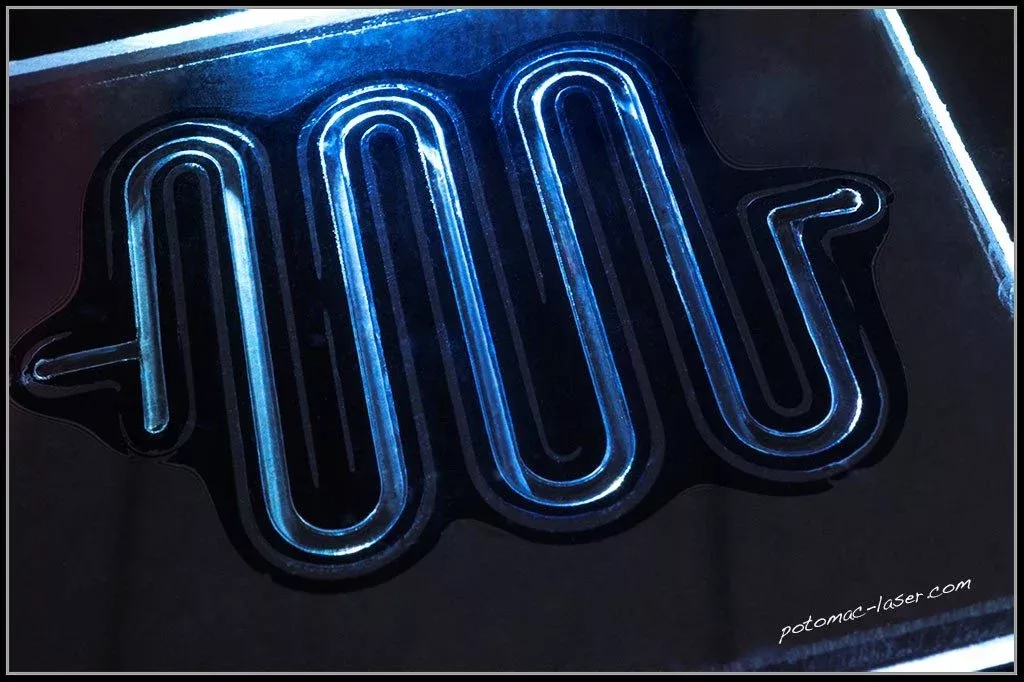

Laser micro-welding offers an effective method for joining a wide range of metal and organic materials. At Potomac, we frequently use pulsed infrared lasers to weld metals and thermoplastics with precision. Achieving optimal results requires careful control of laser energy and pulse duration, along with proper part fixturing to ensure accuracy and consistency.

Precision dispensing of epoxy is often a highly effective method for assembling electronic and optical devices. Potomac has experience with precision placement of epoxies in dot sizes as small as 150 microns, as well as use of encapsulation and underfill compounds.

Micro-welding and Bonding

Laser micro-welding offers an effective method for joining a wide range of metal and organic materials. At Potomac, we frequently use pulsed infrared lasers to weld metals and thermoplastics with precision. Achieving optimal results requires careful control of laser energy and pulse duration, along with proper part fixturing to ensure accuracy and consistency.

Precision dispensing of epoxy is often a highly effective method for assembling electronic and optical devices. Potomac has experience with precision placement of epoxies in dot sizes as small as 150 microns, as well as use of encapsulation and underfill compounds.

Potomac has experience welding stainless steel and NiTi alloys as well as a variety of plastics. Our laser welding systems have been optimized for micromanufacturing through extensive experience with both flat and tubular components.

Industries / Applications include:

- Medical Devices

- Biotechnology

- Electronics

- Automotive

- Aerospace

- Alternative Energy / Photovoltaics