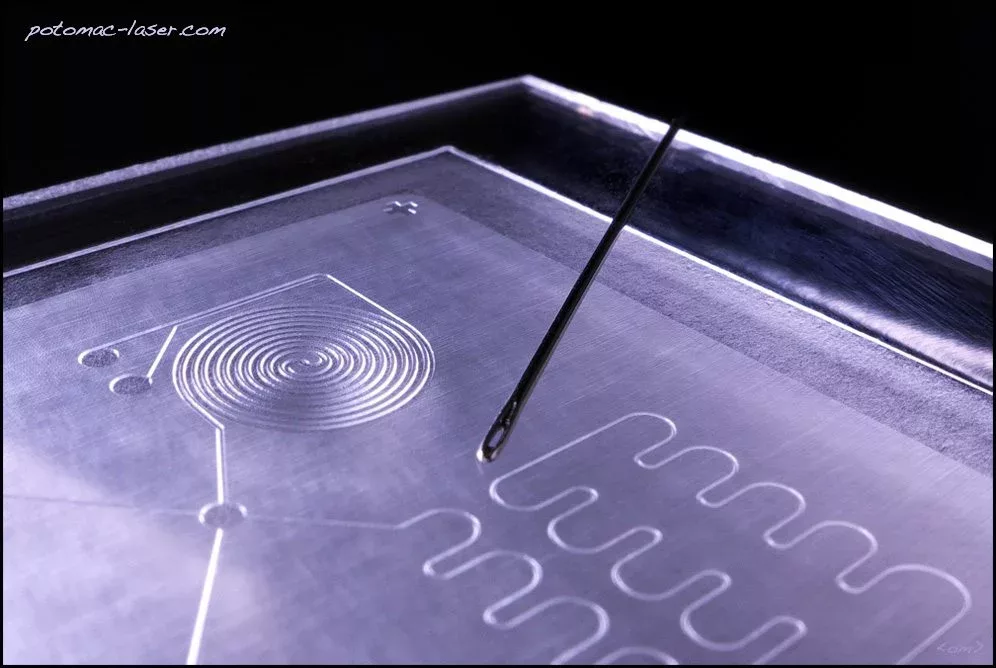

Microfluidic Chip Fabrication: Potomac is your go to company for rapid prototyping of microfluidic chips. Our capabilities include mold fabrication, rapid replication such as hot embossing, hole drilling for ports and bonding.

Microfluidic chip fabrication is a critical process in the development of lab-on-a-chip devices. These chips, characterized by their intricate networks of microchannels, enable precise manipulation of minute fluid volumes. Fabrication techniques leverage principles from the semiconductor industry, adapted to the unique challenges of microfluidic device construction.

Photolithography remains a cornerstone of microfluidic chip fabrication. This process involves the selective exposure of a photoresist-coated substrate to UV light through a photomask, defining the desired channel patterns. Subsequent development and etching steps result in the formation of microchannels with high resolution and reproducibility.

Soft lithography offers an alternative approach, particularly suited for rapid prototyping and fabrication of elastomeric devices. Utilizing a patterned master mold, typically fabricated via photolithography, a soft material such as polydimethylsiloxane (PDMS) is cast and cured to replicate the channel features. This technique is advantageous for its simplicity and ability to generate complex 3D structures.

Other fabrication methods, including etching, embossing, and micromachining, provide further options for creating microfluidic structures, each with its own advantages and limitations. The selection of the appropriate technique depends on factors such as material compatibility, desired feature size and complexity, and production scale.

Once the microchannels are formed, bonding techniques are employed to seal the device, creating a closed fluidic network. Precise alignment and bonding are crucial to ensure leak-free operation and maintain the integrity of the microfluidic architecture.

Advancements in microfabrication technologies continue to drive innovation in microfluidic chip design, enabling the development of increasingly sophisticated devices for applications in diagnostics, drug discovery, and biological research.