Sometimes at Potomac the real power comes when we can combine technologies to solve our customers’ tough manufacturing challenges. In recent years, we’ve added high resolution 3D Printing to our factory toolkit of fabrication machines like laser cutting and marking, micro-CNC machining, and micro hole drilling. Alone, each of these machines is a powerful tool, but the real power comes when we get to combine their capabilities to bring digital fabrication to a new level.

One such project involved creating a microfluidic device for a company in the healthcare industry. We combined high resolution 3D Printing with UV laser micromachining to yield a part that neither technology alone would have technically achieved in a cost-effective manner.

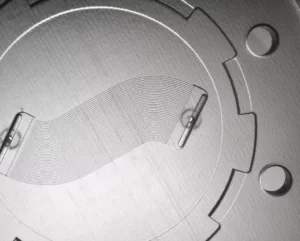

For the macro device, we used our 3D Systems Projet 3000 Plus, a high resolution 3D Printer that could create the 100 – 200 micron features in our customer’s design. The 2” x 2” clear acrylic part could have been traditionally machined but not with such small feature sizes. 3D Printing made the entire device with the features in one step.

But in the next area, 3D Printing could not compete with our UV laser micromachining. The microfluidic device needed channels 10 microns wide and 10 microns deep, a requirement that we’ve perfected in our 30 years in laser micromachining.

Says Potomac President and CEO Mike Adelstein, “In each instance, the tool we used was the right one for the job. Not only could our 3D Printer make the macro parts, they could do so very cost effectively. Laser micromachining would not have made sense from a technical or cost perspective. But for the channels, it was the perfect complementary tool.”

Digital Fabrication requires having the tools and expertise in a variety of technologies, so that we can always offer our customers quick, economical, technically demanding solutions. At Potomac we have all of that, all under one roof.