The addition of state-of-the-art hot embossing equipment will allow Potomac Photonics to make high precision parts at a fraction of the cost of other methods.

December 9, 2013; Lanham, MD: Digital Fabrication industry leader Potomac Photonics, Inc. announces the addition of new hot embossing technology to expand their contract service capabilities.

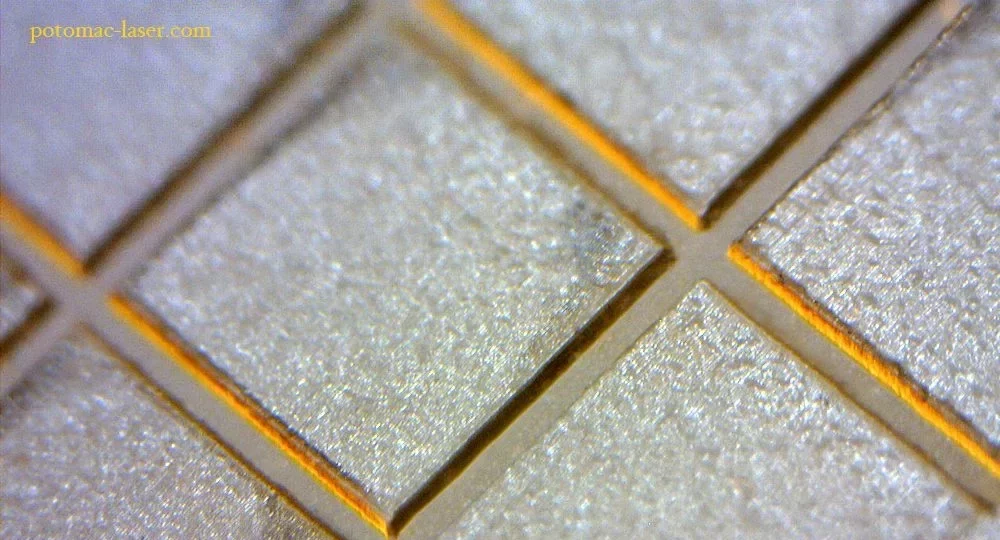

By adding state-of-the-art hot embossing equipment, Potomac is now able to combine this powerful replication technique with laser micro-machined masters to make high precision, high quality parts quickly and at a fraction of the cost of other methods.

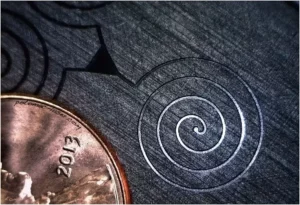

Company President and CEO Mike Adelstein says, “A prime advantage of the Potomac System is that laser micromachining can replace lithography for master generation. We can usually make a master in as little as 24 hours, a substantial improvement in delivery time. An integral part of Digital Fabrication is that we work from a customer CAD File. Design changes are then iterative and our customers can quickly test new ideas or variations. With our UV laser processing we have the flexibility to create features as small as 5 microns with tight tolerances or substantially larger features to meet specific application needs while maintaining quick turnaround.”

Generating the master through laser micromachining is also an order of magnitude less expensive than traditional processes. Mr. Adelstein elaborates, “We want to provide one-stop shopping for our customers which also saves time and energy. To do that we can draw from our many technologies in house to bring your part from prototype to production.”

Microfluidic devices are one example of how Potomac can combine manufacturing processes to complete the entire part or even an assembly. The field is increasingly using polymers, as there are improved performance characteristics at lower cost than glass devices. Laser micromachining fabricates a master; then hot embossing takes over to transfer the design into plastic. Glass or polymer covers can then be bonded onto the device for easier visual inspection while ensuring a good seal that can withstand pressure. For fluid introduction, micro holes can be drilled into the glass and/or polymer. If interface into an assembly is required, Potomac MesoSystems can provide a custom microelectronics solution along with additional packaging.

Rapid prototyping is an obvious use of the new suite of technologies. However, it’s important to note that the hot embossing step can stamp volume parts at once to produce quantities perfect for short production runs. Hot embossing also gives the option of choosing polystyrene, PMMA and Cyclic Olefin Copolymers as materials since they can’t be easily machined either by lasers or micro-CNC to create direct parts.

About Potomac Photonics

For over 30 years, Potomac Photonics has been a leader in microfabrication and small hole drilling. Potomac’s contract services span prototyping to production, helping clients develop miniature products and bring them to market. Using cutting-edge manufacturing technology, Potomac has been recognized by both commercial and government agencies for innovation in areas such as medical device, electronics, aerospace, and automotive manufacturing. Potomac’s high-tech facility, located in Lanham, MD, is ISO 9001:2008 and ISO 13485:2003 certified.