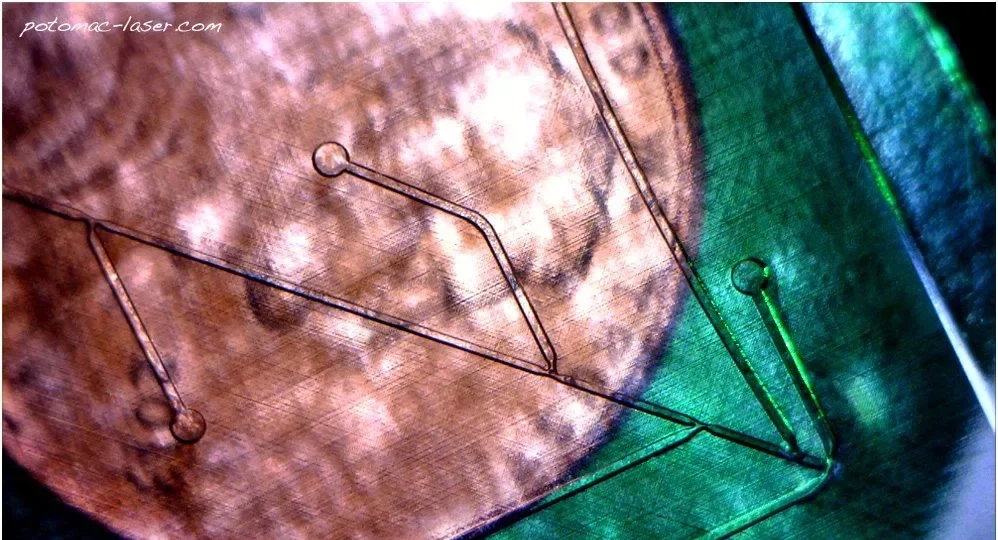

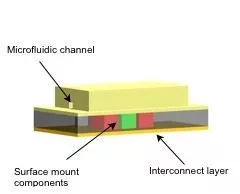

Over the past few years, Potomac Photonics and Potomac MesoSystems have been developing new techniques for building highly miniaturized electronic systems in which the smallest surface mount electronic components are embedded in a thermoset epoxy block and interconnected with fine-feature nanoparticle silver conductors. With support from the National Science Foundation (SBIR PhII Grant 1058133) we’ve perfected this approach and investigated applications in miniaturized wireless sensing. Applications also exist in microfluidics, and there are many ways in which a structure like the one shown here could be used in heating, cooling, characterizing and controlling fluids flowing in a microfluidic channel.

Recently, we started a joint project with a group in the Mechanical Engineering Department at UMBC to explore a first microfluidic application. Prof. Tony Farquhar and Ph.D. student Amir Harandi have carried out in-depth studies of heating and cooling of microfluidic structures using patterned copper structures for heat transfer. In the course of their work, they’ve developed a thorough understanding of issues involved in heating and cooling of microfluidic systems, techniques for local temperature measurement, and a lot of expertise in thermal modeling and analysis. We’ll be working with UMBC to develop simple and inexpensive methods for customizable thermal distributions in a microfluidic structure using surface mount electronic components

Potomac manufacturing techniques used in this article:

- Hot Embossing of microfluidic channels

- Bonding and assembly

- Precision hole drilling

- Integration of highly miniaturized electronic systems to microfluidic devices