January 15, 2015; Baltimore, MD: Potomac Photonics, a pioneer in the R&D and manufacture of excimer lasers for the medical device and biotech industries, recently tapped Coherent to increase the number of ultraviolet lasers in the company’s micromachining contract service production facility. Potomac’s digital fabrication center at bwtech@umbc includes lasers from the infrared to the ultraviolet, along with 3D Printers, hot embossing equipment and micro CNC machines.

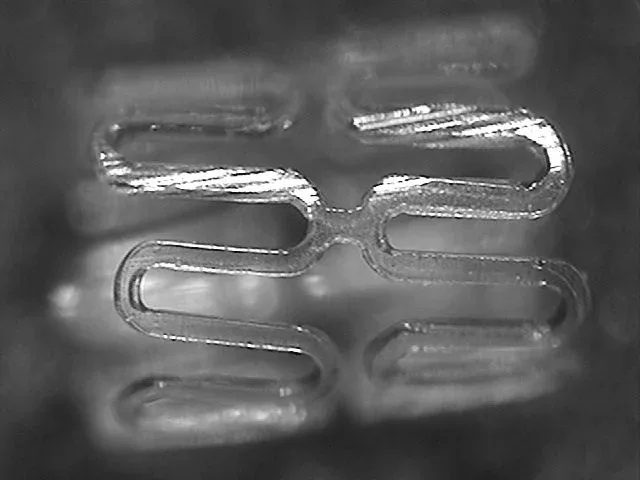

While advances in solid-state laser technology have increased the viability of non-gas lasers for production work, wavelengths far into the UV are still needed for certain applications. The new compact excimer from Coherent is set up to operate at 248 nm, a wavelength that is strongly absorbed by a variety of materials including organic polymers, glass, and diamond. Further, at these short wavelengths, the photon-material interaction is essentially non-thermal, creating no heat affected zone [HAZ]. The resulting edge quality makes the excimer laser the laser of choice for cutting or hole drilling in materials such as polyimide, polystyrene and PEEK.

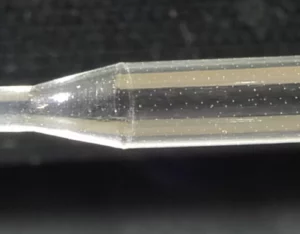

Short wavelength lasers also are easily focused to small spot sizes. With the excimer laser, Potomac can create holes as small as one micron with accuracy and repeatability. Since excimer lasers also generate light at the fundamental and do not have to be frequency multiplied, the beam is stable for consistent production on the Potomac factory floor.

“While we use a number of different laser types for specific applications,” explains Potomac President and CEO Mike Adelstein, “the excimer is our workhorse. Since the founding of the company in 1983 to design and build miniaturized excimer lasers, we have worked extensively with our customers to develop unique processes to advance the field of laser micromachining. Building our own lasers in the early days also gives us the expertise to optimize the lasers we purchase especially for the demanding applications we see on a daily basis.”

Excimer lasers are especially well suited to medical device and biotech applications. With devices shrinking in size, high precision is needed to fabricate parts and since so many are now implanted into the human body it’s essential there be no charring or burning; in other words, these applications tolerate zero HAZ.

In recent years, Potomac has built a contract service facility that now includes complementary manufacturing technologies such as 3D Printing and micro CNC machining. But leadership and expertise in excimer lasers and UV laser micromachining is the cornerstone of the company’s digital fabrication toolbox, driving the integration of technologies to give unique solutions to customer product development and production problems.

For over 30 years, Potomac Photonics has been a leader in microfabrication and small hole drilling. Potomac’s contract services span prototyping to production, helping clients develop miniature products and bring them to market. Using cutting-edge manufacturing technology, Potomac has been recognized by both commercial and government agencies for innovation in areas such as medical device, electronics, aerospace, and automotive manufacturing. Potomac’s high-tech facility, located at BWTech@UMBC Research and Technology Park , is ISO 9001 and ISO 13485 certified. Visit the website at www.potomac-laser.com