In the early days of microfluidics research, devices were most commonly fabricated in silicon or glass. Material options were limited because photolithography was used for manufacturing chips. Glass in particular was seen as a good choice since it is optically transparent and electrically insulating, as well as being an amorphous material.

But times have changed. Laser micromachining is now commonly used to prototype and produce microfluidic chips, offering a significantly wider range of material options. Organic polymers have fast become more viable materials than silicon or glass since they exhibit excellent material properties while also being less expensive both in purchase price and cost of processing.

Features

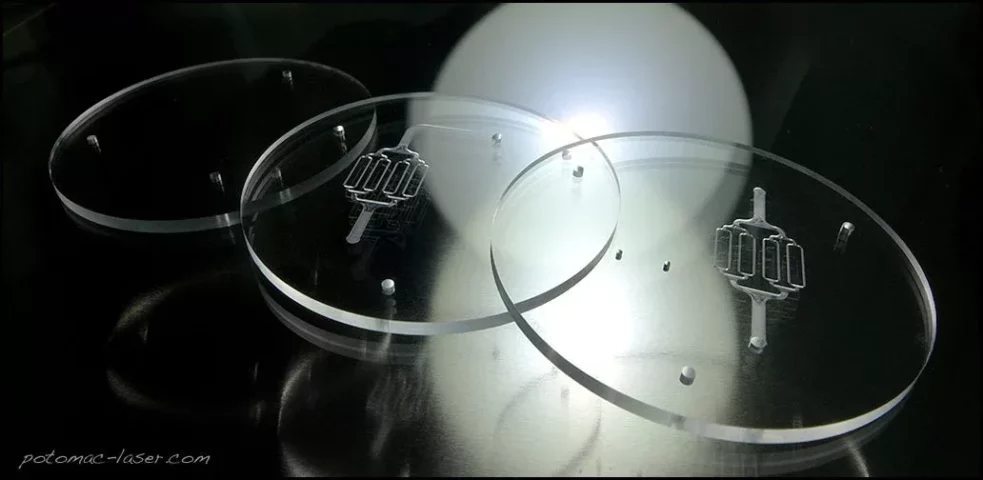

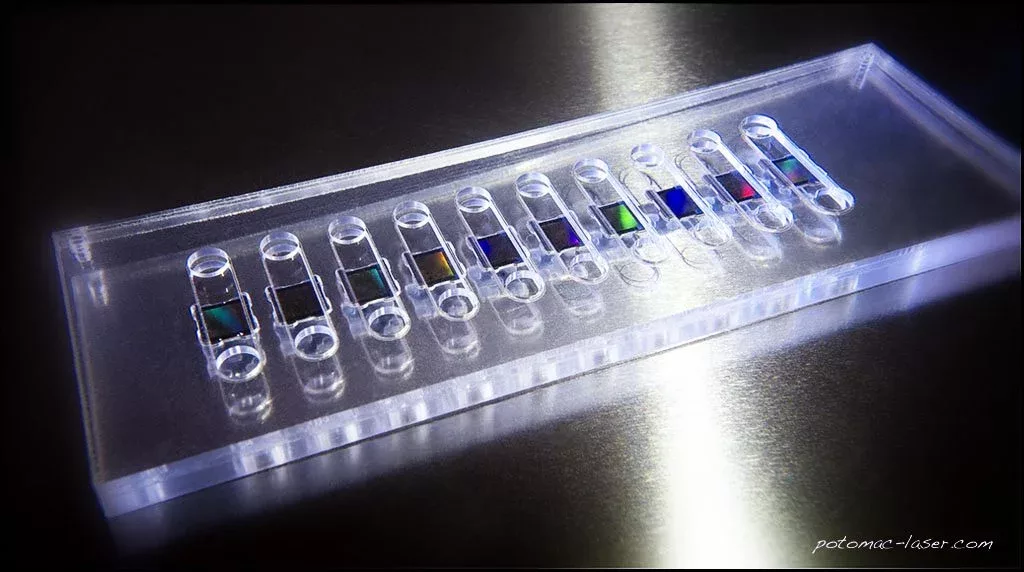

Poly-methyl methacrylate (PMMA) is an inexpensive polymer that has become one of the most commonly used materials in microfluidic systems. Despite its low cost, PMMA offers the essential properties required to fabricate high-quality devices. It is rigid, possesses excellent optical transparency, and is compatible with electrophoresis—a critical feature for various research applications. Potomac routinely laser micro-machines PMMA with excellent results. We have also developed complementary processes for manufacturing microfluidic devices in production once prototypes are optimized. Bonding chip layers is an especially important process in building microfluidic chips. The process must create strong bonds while not allowing the fluid channels to collapse. Individual layers of the device are first fabricated by using rapid microfabrication technologies such as lasers, micro-CNC, hot embossing, 3D printing, etc.

It is noteworthy that Schott, a company with over 125 years of manufacturing history that began as a glass factory in Germany, now produces an innovative polymer increasingly utilized in microfluidics. Cyclic olefin copolymers (COCs) are advanced composites made from various cyclic olefin monomers and ethene. In addition to its affordability, COC is highly moldable and easy to fabricate. The manufacturer Topas reports a total light transmission of 91.4%, combined with exceptionally low chromatic aberration. These optical properties make COC an ideal material for use in components such as camera lenses and laser printer optics. In microfluidic systems, COC is an excellent choice due to its biocompatibility and high chemical resistance. It also can be sterilized with a wide variety of techniques.

Because of its crystalline structure, glass tends to crack when cut either mechanically or with laser machining. Potomac has developed successful processing techniques that eliminate cracking. But it is time consuming and requires much more expertise than machining plastic. Whether fabricating our tiniest features down to one micron or manufacturing larger parts, plastics machine quickly and easily. Consequently, the cost to machine glass is exponentially higher than for plastics.

If you’re not sure about switching to polymers from glass for your microfluidic systems, try a quick test. Potomac can economically make you a plastic part for your comparison, and we predict you’ll never look back.