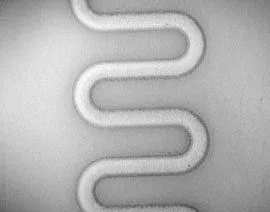

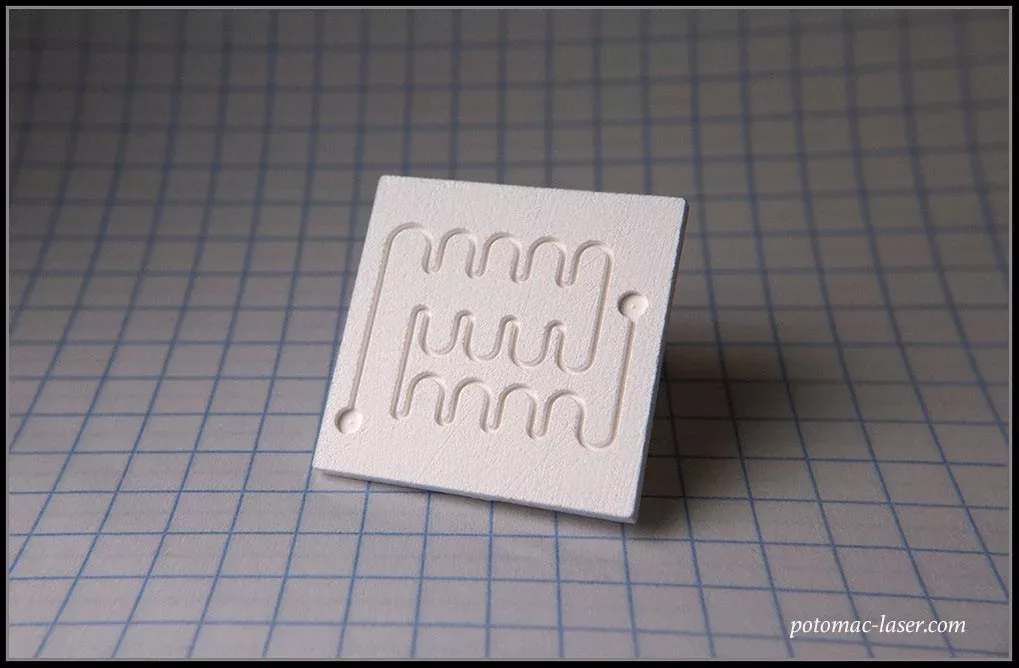

Various types of ceramic and crystalline substrates can be processed, including alumina, silicon nitride, silicon, diamond, and sapphire. In many cases, laser-based processes, such as those used by Potomac, are the only viable solution for the precision machining of these challenging materials. Feature sizes, depending upon thickness of the substrate, can be as small as 25µ with excellent edge quality, minimal microcracking and no heat-affected zone.

In many cases, Potomac is capable of laser machining through-holes, blind holes, channels, slots, and other geometries in both flat and 3D substrate configurations.

Custom Ceramic Parts for the Medical, Biotech, Automotive and Electronics Industries

Applications include probe cards, fiber guides, microfluidics and more.

All that is required to get started is a drawing of your part.

micromachine ceramic materials

Ceramic Materials

Some of the ceramic materials that Potomac can micromachine include:

Alumina is the most widely used ceramic material. It offers excellent performance in terms of wear resistance, corrosion resistance and strength at a reasonable price. Its high dielectric properties are beneficial in electronic products.

Silicon nitride offers an excellent combination of low density, high strength, low thermal expansion and good corrosion resistance and fracture toughness.

Silicon carbide has the highest corrosion resistance of all the advanced ceramic materials. It also retains its strength at temperatures as high as 1400°C.

Zirconia has the highest strength and toughness at room temperature of all the advanced ceramic materials. The fine grain size allows for extremely smooth surfaces and sharp edges.

Single crystal sapphire offers superior mechanical properties and chemical stability coupled with light transmission.