Blog Post

The Year Ahead for Potomac

2013 was an exciting year for Potomac in terms of growth, new capabilities, new equipment and great collaborations with our customers. We expect 2014 to bring even more activity aimed to give customers the best Digital Fabrication services in the industry.

Here are the highlights of what’s ahead in the coming year:

Expansion to BWTech@UMBC

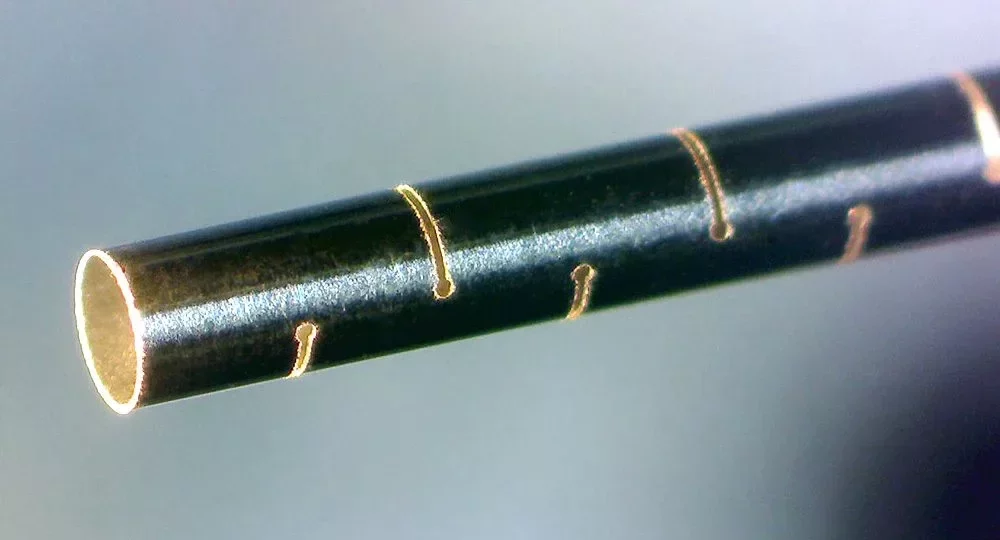

As we mentioned in an earlier blog post, Potomac is moving to a new high tech facility at the University of Maryland, Baltimore County. The move will be 60% complete by January 1, 2014, and final by spring. A clean room and new equipment, such as machines for hot embossing and bonding, allows us to expand beyond micro-fabrication to creating complete assemblies and products for a wide range of industries. Our Digital Fabrication toolbox will continue to expand as we collaborate with faculty, students, and staff to add new technologies to our 30-year core competency in laser micromachining.

As we mentioned in an earlier blog post, Potomac is moving to a new high tech facility at the University of Maryland, Baltimore County. The move will be 60% complete by January 1, 2014, and final by spring. A clean room and new equipment, such as machines for hot embossing and bonding, allows us to expand beyond micro-fabrication to creating complete assemblies and products for a wide range of industries. Our Digital Fabrication toolbox will continue to expand as we collaborate with faculty, students, and staff to add new technologies to our 30-year core competency in laser micromachining.

Joint R&D

An example of how we plan to leverage our relationship with UMBC is an R&D project we are funding between the Dept. of Mechanical Engineering and our sister company, Potomac MesoSystems. Working with a PhD Candidate, Potomac founder Dr. C. Paul Christensen will be investigating the integration of microelectronics and sensors with microfluidic devices. This is a burgeoning field and we are committed to being part of the R&D for next generation devices.

3D Systems Corporation Authorized Re-seller

Potomac is an authorized re-seller of 3D Printers manufactured by industry leader 3D Systems. At the new facility, Potomac plans to expand our work helping customers choose the right production equipment for their applications. We are in a unique position in that we can assist with development of specific manufacturing processes then train customers on the 3D Printers they bring in-house.

Potomac is an authorized re-seller of 3D Printers manufactured by industry leader 3D Systems. At the new facility, Potomac plans to expand our work helping customers choose the right production equipment for their applications. We are in a unique position in that we can assist with development of specific manufacturing processes then train customers on the 3D Printers they bring in-house.

Education

The world of Digital Fabrication is growing exponentially, especially with the advent of 3D Printing. Partnering with the non-profit FabLab Hub, we will soon be offering workshops for designers, engineers, innovators and entrepreneurs. With our extensive, practical experience, Potomac can cut through the hype with solid data about the potential – and challenge – of Digital Fabrication methods.

Of course we would not be able to do any of this without our great customers, whose challenging fabrication problems drive our expertise to higher levels. With many thanks to everyone for a great 2013, and Best Wishes for a fantastic year to come!