At Potomac we like to say that despite the mainstream media hype, 3D Printing is not yet the Star Trek replicator. The same is true for all the technologies we use to make products for our customers. From prototype to production, manufacturing tools are seldom a one-stop solution to making anything and are often used together for the best solution.

Digital Fabrication tools such as laser micromachining, 3D Printing, and micro hole drilling each have specific capabilities that make them the optimal choice for a job. Potomac’s expertise is built on the knowledge of when to use which technology for the highest quality, most economical result.

Laser micromachining, especially for medical device and biotech applications, offers a unique set of capabilities that shine for specific manufacturing requirements such as

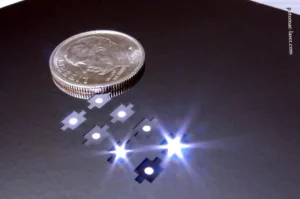

- small hole size: with our UV lasers we can make holes or spot sizes as small as one micron.

- little or no HAZ: in the UV especially, cutting is not a thermal process so there is little or no heat affected zone which is why lasers were chosen for LASIK eye surgery. we have also perfected laser techniques to cut and drill different types of materials with extremely clean edges.

- strong absorption by many materials especially at 248 and 193 nm: we work with materials as diverse as organic polymers, ceramics, metals and diamond.

- ability to make blind vias: pulsed lasers allow us to control drilling depth to stop before drilling through the entire thickness of a material.

- repeatability and accuracy: computer controlled machines ensure ultra high precision for large arrays of holes and designs.

In this upcoming series of blog posts, we will be exploring these 5 traits of laser micromachining and describing in detail specific biotech, medical device, and other applications for which each capability is especially well suited.

Watch this space over the next 5 weeks to learn more about the benefits of laser micromachining and how they can help manufacture your products cheaper, quicker and easier.