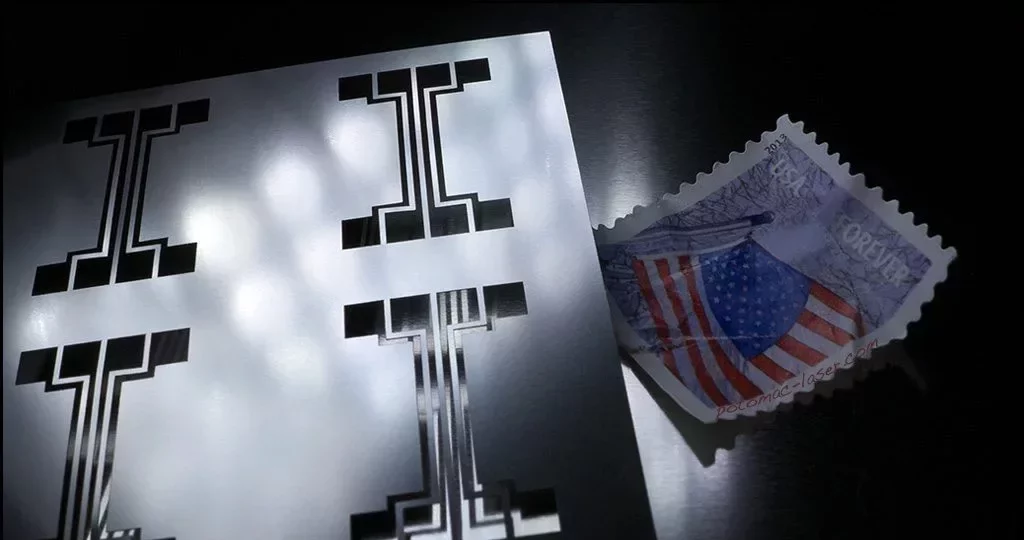

When we need to make very small holes, cuts, lines and features laser micromachining is usually the best choice in our digital fabrication toolbox. Lasers that emit light in the ultraviolet region of the spectrum are especially useful in biotech and medical device applications since they can create features as small as 1 micron – which is pretty small if you consider that the average human hair is about 75 microns in diameter!

Laser Wavelength

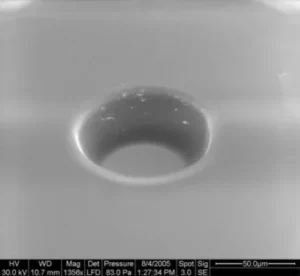

Laser beams must be focused down to a spot size where the energy can be sufficiently concentrated in order to cause a material change. Lasers operating at shorter wavelengths, such as excimers at 193 and 248 nm, can be focused to sub-micron spot sizes. Although this is feasible, in practice, repeatable spot sizes can measure about 1 micron, making the light source very useful in many applications. Holes in the 1 to 20 micro range are often used for leak testing, and manufacturing medicinal nebulizers, inhalers, balloon catheters or shadow masks.

Try as one may, light in the longer wavelength area of the infrared will never physically be able to make such small holes. However, for many applications, holes between 5 and 200 microns do the job. In those instances, especially when working with metals, ceramic, silicon or glass, longer wavelength lasers are chosen for optimal results.

Aspect Ratio

We must also take into account the aspect ratio, that is, the relationship between the diameter of the laser spot size and the thickness of the material. While we focus laser light down for maximum energy concentration or fluence, once the photons are absorbed into the material the beam expands or diverges. As a rule of thumb, the divergence of laser beams increases as spot size decreases.

A beam focused to a 1-micron spot only maintains that spot size for a short distance so manufacturing 1-micron holes in 6” of material is physically impossible. At Potomac we have a number of techniques that

allow us to achieve as much as 10:1 aspect ratios, so that we can make a hole that is 10x deeper than its diameter. But this is dependent upon a number of factors including type of material.

Although mechanical processes have their place, CNC machining simply cannot match lasers’ unique ability to make holes on the smallest spatial scales. With so much miniaturization in the biotech, medical device, microfluidics, electronics and consumer products industries, product parts need smaller and smaller features.

Since Potomac started out developing and building excimer and other UV lasers, we are uniquely qualified to choose the right laser to solve the smallest manufacturing problem.