All material processing starts, of course, with the material. Laser micromachining is a good option for manufacturing parts since materials absorb light resulting in a physical transformation of the material’s structure. Whether it’s a thermal process as with infrared lasers or the ultraviolet lasers’ photo-ablative mechanism, laser light can drill holes, cut, weld, and mark a wide variety of materials. But for optimal machining results it is imperative to choose a laser that emits light at the wavelength most suited to the material.

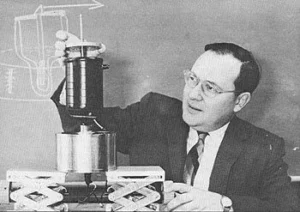

The late Arthur Schawlow, co-inventor of the laser, was a showman and used to conduct a fun demonstration of how different materials absorb laser light. Using an early laser – in the shape of a ray gun – he would shoot the beam into a clear balloon made of a material that simply transmitted the wavelength without absorbing it. The photons would pass through to the interior where a balloon in the shape of Mickey Mouse made of a different material absorbed the light and popped with out damaging the external material. It’s a clear demonstration of how different materials absorb or transmit light based upon the photon’s wavelength.

At Potomac, we utilize a number of lasers ranging from the infrared to the UV in order to be able to select the right laser wavelength for the material we are processing. CO2 lasers have been used for years as the workhorse of the automotive industry as metals absorb strongly in the infrared region. We are able to drill holes in stainless steel, copper, titanium, and aluminum nozzles, shadow masks and filters with consistency and repeatability.

For some materials such as organic polymers, human tissue, diamond and even quartz, the invention of commercial lasers operating in the far UV has opened up a number of applications. Excimer laser light at 193 nm for example is strongly absorbed by just about all materials and allowed for recent innovations including LASIK eye surgery.

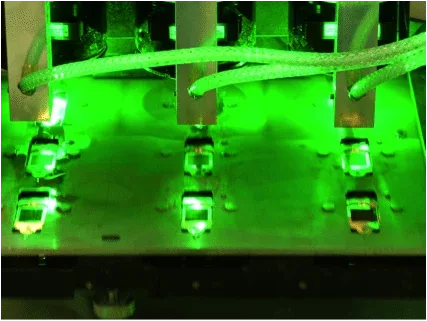

Potomac uses excimer lasers at 248 and 193 nm to fabricate a wide variety of medical device and biotech products. Organic polymers are used in catheters and other disposable devices, as well as to manufacture microfluidic devices, so excimer laser micromachining is our first choice for these applications.

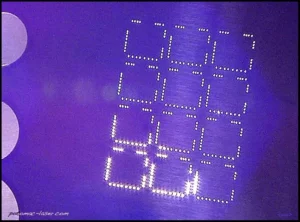

Glass is an especially challenging material to machine mechanically making laser micromachining the best choice given its non-contact properties. Variation between the types of glass must be factored in, but most glass absorbs best somewhere in the ultraviolet region. While we see many applications for leak testing and other hole drilling, this limited absorption spectrum also makes glass a great substrate for conductive coatings or films where precise patterning is desired without damaging the glass.

There are a number of other considerations Potomac takes into account when choosing the right tool for a job that we’ll discuss in upcoming posts, but first and foremost, Potomac matches the material absorption to the laser wavelength to give our customers optimal micromachining results.