We live in such an inspiring time, when technology is transforming access to new areas of collaboration and research. Once such example of open access in the area of microfluidics is MIT’s new Metafluidics.org website, a free repository of designs for lab-on-a-chip devices. Designs can be submitted by anyone ranging from trained scientists and engineers to hobbyists and students. A user need only browse the site to find devices ranging from simple cell sorters and fluid mixers, to more complex chips that analyze ocular fluid and synthesize gene sequences.

Perhaps more importantly, the site serves as a social platform for the microfluidics community where users can share and interact. For in our complex world, more often than not, collaboration is the key to unlocking innovation.

David S. Kong, director of the MIT Media Lab’s new Community Biotechnology Initiative, is no stranger to open source platforms. He comes out of the MIT Center for Bits and Atoms where Director Neil Gershenfeld encourages use of open source platforms to solve challenging digital fabrication problems.

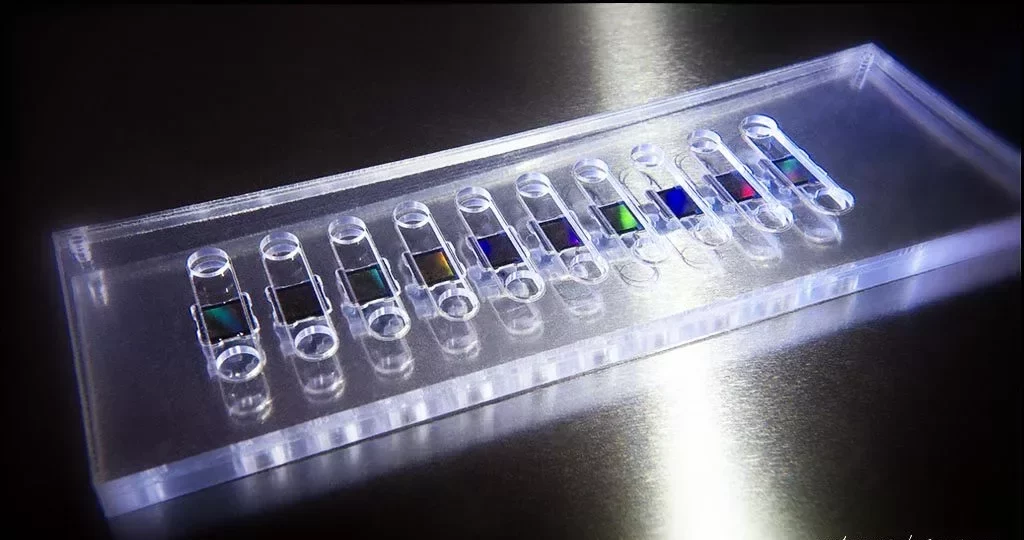

In our own experience, Potomac has seen the power of collaboration. For microfluidics research we have developed a number of capabilities that push the envelope for our customers. Starting with a basic design, perhaps from the Metafluidics website or a back of the envelope simple drawing, Potomac has the expertise to take an idea and translate it to a CAD design that our digital manufacturing tools can turn into something you can test in real lab situations. Ideas are great, but we can bring those ideas to life!

Our Fast Track microfluidic program quickly and economically rapid prototypes designs with specific parameters but we also offer services for custom designs that are specific to your needs. Check out open source designs and when you need them fabricated, Potomac is here to help you fabricate and iterative designs for your specific application in order to speed your product’s time to market.