New technologies and advances in automated machinery have given rise to a host of new contract service providers in the digital fabrication market. But Potomac is different in that we do more than just purchase off the shelf machines. Here at Potomac we have a 30-year history of R&D to drive fundamental understanding and improvement in digital fabrication tools and processes. Potomac’s depth of knowledge helps our customers solve their manufacturing problems in unique and cost-effective ways that standard tools can’t match.

One of Potomac’s new areas of work is fabrication of advanced microfluidic devices. We’re using new technologies such as hot embossing and 3D Printing in combination with laser micromachining to reduce fabrication time and cost. As we manufacture for specific applications, customers are requesting advanced characterization and control of the fluids in the devices. Responding to customer challenges, Potomac founder Dr. Paul Christensen started an R&D project to address the problems and also tapped the Mechanical Engineering Department at the University of Maryland, Baltimore County [UMBC].

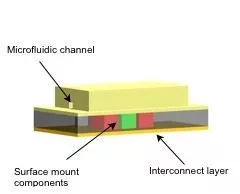

Dr. Christensen’s new microfluidic R&D project draws from PotomacMeso’s recent results generated by a National Science Foundation SBIR Phase II grant to investigate new techniques for building highly miniaturized electronic systems. He has devised ways to embed the smallest surface mount electronic components in a thermoset epoxy block and interconnect them with fine-feature nanoparticle silver conductors. A sample structure is shown here.

At UMBC, Professor Tony Farquhar and Ph.D. student Amir Harandi have carried out in-depth studies of heating and cooling of microfluidic structures using patterned copper structures for heat transfer. In the course of their work, they’ve developed a thorough understanding of issues involved in heating and cooling microfluidic systems, techniques for local temperature measurement, and expertise in thermal modeling and analysis.

It is our hope that both research areas can be combined to develop simple and inexpensive methods for customizable thermal distributions in a microfluidic structure, using surface mount electronic components. Watch this space for updates on the R&D, as Potomac drives digital fabrication forward for improved microfluidic devices.