Cells. The smallest units of life. They make up who we are, and so, it’s imperative we become progressively educated about them. Cell culturing allows scientists to grow and maintain cells, in vitro. Researchers at the University of California, Santa Cruz are currently developing a more efficient way to monitor human cell cultures, encased in microfluidic device channels.

For concentrated research, the cell cultures require close examination, and therefore must be inspected underneath a microscope. Their team is working to build microelectrode arrays, to monitor the cell cultures from the chip, itself. Because the scientists want the greatest possible clarity of the cultures, they have figured a way to fix the microfluidic device for optimal visuals of the cultures.

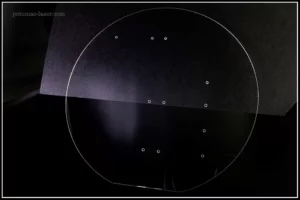

Potomac drilled the university’s requested holes for the devices into borosilicate glass substrate. Using a UV laser to drill the holes, the technicians successfully fabricated the devices, minimizing the consequences of heat produced by standard lasers.

The holes allow the researchers to “build all the fluidic connections”, as UCSC’s John Selberg put it, on the backside of the device. By doing this, they can image the front side, without interference between the cells and the microscope.

Cells must work cooperatively for their host to function and to accomplish a common goal–to maintain homeostasis. With a project like the one for UCSC, the company must act similarly. Departments like Production and Quality Control work in tandem to provide the best part for the customer’s needs.

We wish the University of California, Santa Cruz luck on their impressive scientific endeavors!