Digital fabrication processes such as laser micromachining and 3D Printing have had enormous impact on manufacturing by allowing for rapid prototyping and testing of new product designs. These digital fabrication tools are driven by instructions from a computer aided design [CAD] file, so that any changes are made quickly and easily on the computer. With the ability to try different ideas, designers and engineers can contrast and compare results in new products in an iterative process flow. Everyone is then sure that the design that makes it to production is the best choice to meet customer needs, which of course helps spur sales.

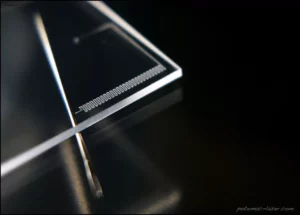

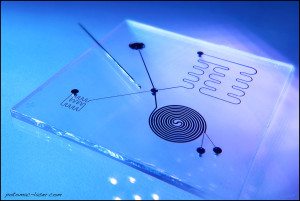

With the introduction of FAST TRACK, Potomac brings true rapid prototyping capabilities to microfluidic device manufacturing. The new digital fabrication process quickly and economically manufactures complete custom microfluidic devices for the biotech and medical device industries. The operative word here is: custom. From a .dxf format CAD drawing, small quantities of a device can be fabricated for testing in order to optimize the design parameters.

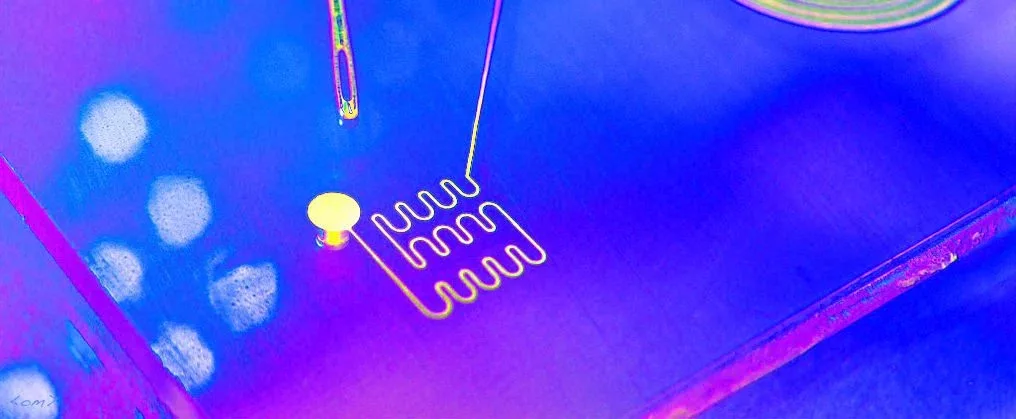

Changes are simply made in the CAD software, so there is no expensive tooling and no time waiting for molds or masks to be generated. Want to try a different channel configuration or alter the placement of vias and holes? No problem! Simply create a new CAD file and Potomac can generate and precisely replicate channel designs in a polymer substrate, laser micro-machine vias and holes, and also bond cover slips to create a finished microfluidic device that is customized for specific applications.

We think that David and Tom Kelley, founders of IDEO and Stanford’s d.school [institute of design] give important reasons for always using rapid prototyping in their new book, Creative Confidence. The famous product design team states that “The reason for prototyping is experimentation—the act of creating forces you to ask questions and make choices. It also gives you something you can show to and talk about with other people…Some failure is unavoidable. So you need to relentlessly seek out clever new ways to create low-cost experiments. The best kinds of failures are quick, cheap, and early, leaving you plenty of time and resources to learn from the experiment and iterate your ideas”.

FAST TRACK’s microfluidic device fabrication process does just that. It’s fast turnaround and low price if you can stick to specific design parameters that are listed on the Potomac website Fast Track page. These include material choices for substrates and bonding, as well as channel and hole sizes. Rapid prototyping a minimum of 10 parts cost $90 per part assuming you can work within this framework. As volumes increase, cost is reduced to less than $15 per part.

For other design parameters, Potomac’s digital fabrication staff can work with you on process development to rapid prototype within your constraints; however, pricing will change according to the complexity of the microfluidic device design modification. Contact Potomac to review your design and learn more about the FAST TRACK program.