One of the main reasons Potomac relocated to the BWTech@UMBC South Technology Park was to access the talent being cultivated at one of the country’s leading STEM education universities. While recently grabbing basketball headlines, the University of Maryland Baltimore County is better known for its commitment to training scientists and engineers and we are lucky enough to work with their stellar students and staff.

One of the main reasons Potomac relocated to the BWTech@UMBC South Technology Park was to access the talent being cultivated at one of the country’s leading STEM education universities. While recently grabbing basketball headlines, the University of Maryland Baltimore County is better known for its commitment to training scientists and engineers and we are lucky enough to work with their stellar students and staff.

The 2018 Spring semester we had the opportunity to offer an internship to Marios Levi, a mechanical engineering junior with a minor in entrepreneurship and innovation, who has a drive to learn. Marios had first connected with one of our people through LinkedIn. So when he was accepted into the Shattuck Family Internship Program for Entrepreneurship Innovation and Social Change, the Potomac name jumped out from the long list of possible internship partners. This unique program places highly-motivated students from diverse backgrounds in mentored internships to better prepare them to launch start-ups and empower them to become the next generation of entrepreneurs or nonprofit leaders.

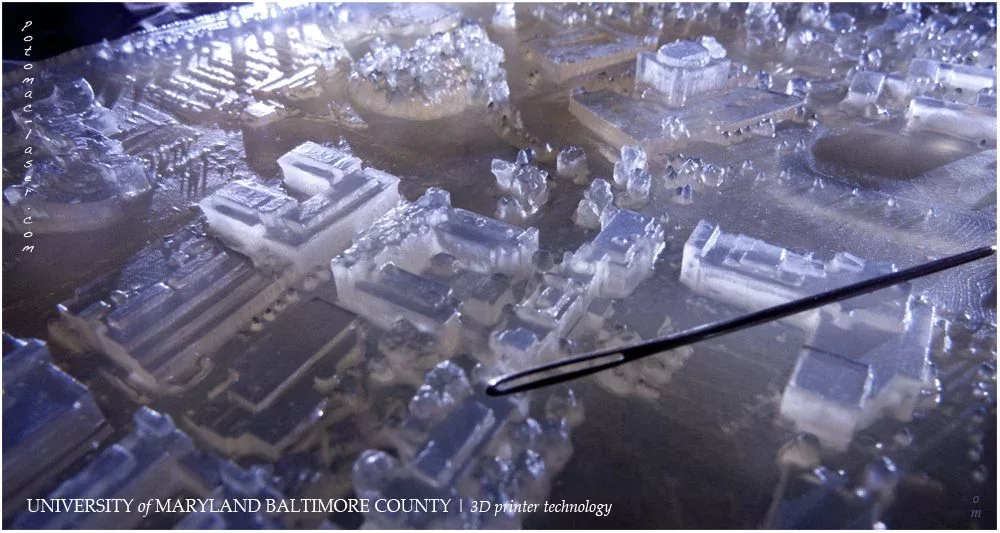

“Since I am interested in 3D Printing,” says Marios, “Potomac was a natural fit.” He started as a hobbyist, buying a used printer on Craigslist while in his freshman year. But soon Marios was hooked on the technology and wanted to expand his horizons in the business-to-business space. He saw Potomac as the opportunity to learn more in this area of digital manufacturing. He explains, “The biggest benefit was learning what is possible with modern technology and knowing what is feasible when a customer asks for a solution to a problem. Potomac’s high precision with micro accuracy opened a new world to me!”

Marios thinks the future of 3D Printing will be in mass customization, an important element in biotech, medical devices and personalized medicine. While he was primarily interested in 3D Printing, the Rockville, MD native wanted to gain experience in other manufacturing technologies like laser cutting. Potomac’s wide range of digital fabrication tools exposed him to a variety of options in choosing the right tool for a materials processing job.

“Mechanical engineering is a broad topic”, points out Marios, “and I wanted to focus on a specific area. Applications in micro-manufacturing were especially interesting and I could see progress with my work.” Potomac also presented a real-world exposure to solving problems for customers. In one case he and his Potomac mentor 3D Printed a fixture that allowed them to bend a thin piece of metal for a job. In another instance they calibrated the industrial 3D Printer in order to more easily meet specifications for an NIH job.

Reiterates Potomac President and CEO Mike Adelstein, “We think giving students an opportunity to experience what it’s like to work in a real customer environment, best prepares them for the modern manufacturing workplace.”

Potomac looks forward to training more of the next generation in digital manufacturing!