SME’s RAPID Conference and trade show clearly has its finger on the pulse of additive manufacturing. In the last few years we’ve seen exponential 3D Printing developments that are driving advanced manufacturing in the Biotech, microfluidics, microelectronics, consumer products and medical fields.

At Potomac, 3D Printing is an integral tool on our factory floor. By continually expanding our capabilities for solving challenging customer fabrication problems, we can choose the right tool for a specific job. Whether using laser micromachining, micro CNC machining, laser welding, bonding, or molding, Potomac’s tools and processes provide a depth of expertise unmatched in the industry resulting in innovative approaches. Our ability to draw from many different technologies, also allows us to come up with creative ways to combine tools for unique processing options since often no one tool can do it all.

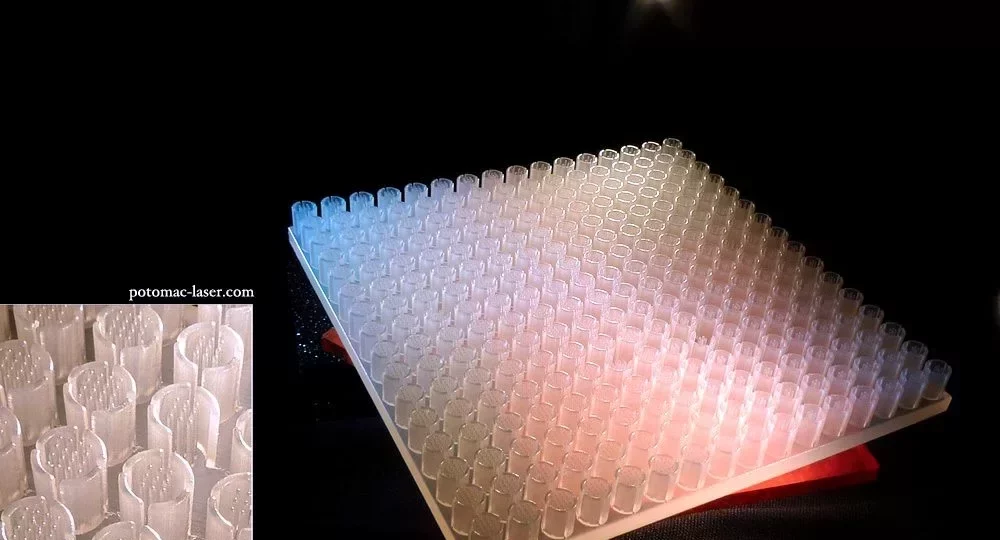

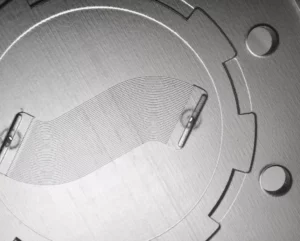

3D Printing is a case in point. While the additive manufacturing process offers novel fabrication capabilities such as the ability to design complex geometries, there are still limitations in creating small feature sizes, speed for production runs and material selection. Taking advantage of the best features of each technology allows us to dig into the toolbox on our factory floor for the right machine choice. Often, that is a combination of technologies. For the 13-micron wide channels in the microfluidic device pictured here, we turn to UV laser micromachining after 3D printing the substrate. The combination gives us just the right mix of benefits, allowing us to optimize the part’s manufacturing.

3D Printing is one of the best choices for rapid prototyping, so it is natural that the RAPID conference now focuses heavily on additive manufacturing. Parts can often be produced overnight, greatly reducing turnaround. Being a digital fabrication tool, designs can be tested and iteratively modified to create the best product and speed time to market with higher chance of sales success.

Potomac’s work utilizing 3D Printing and other technologies in our advanced manufacturing facility will be featured in a talk at RAPID. The presentation will explain how we have developed hands-on internship programs in collaboration with local schools in order to help foster a pipeline to engaging work in the Factory of the Future utilizing a wide range of manufacturing tools and technologies.