With Labor Day approaching it’s a great time to celebrate the advanced manufacturing contributions our skilled staff make to the many biotech, medical devices, microfluidics, displays, microelectronics and other products that impact the lives of so many. In honor of our fabricators on the factory floor, we’re launching a video series featuring the elements of our digital fabrication work as seen through the eyes of the operators, technicians, engineers and managers who make up Potomac.

With Labor Day approaching it’s a great time to celebrate the advanced manufacturing contributions our skilled staff make to the many biotech, medical devices, microfluidics, displays, microelectronics and other products that impact the lives of so many. In honor of our fabricators on the factory floor, we’re launching a video series featuring the elements of our digital fabrication work as seen through the eyes of the operators, technicians, engineers and managers who make up Potomac.

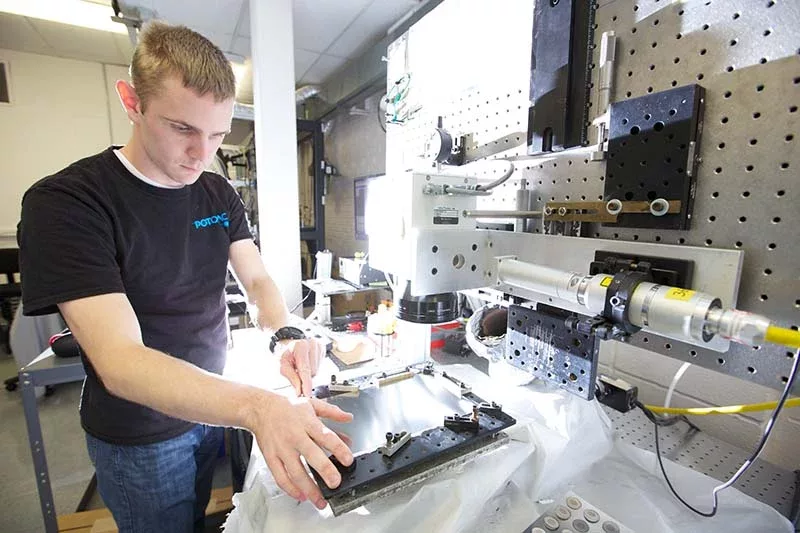

In the first video our Vice President of Manufacturing, Mike Davis, gives us a behind the scenes look at laser micromachining. Drilling and cutting with UV lasers allows us to reach the small spatial scales needed for high precision manufacturing of new innovative products such as Lab on a Chip analysis tools and drug delivery devices for personalized medicine. UV Laser micromachining routinely creates spot sizes between 1 and 200 microns, and we have developed fast processing speeds to meet the demands of long production runs creating tens of thousands of holes in just a few minutes.

UV light also interacts with just about all materials and we’re able to drill holes or process other shapes in organic polymers, glass, ceramics, plastics, silicon, diamond and metals. Because the material interaction with UV light is not a thermal process, there’s the added benefit of little or no damage to the part being manufactured. It’s actually UV light that’s used as the basis of LASIK eye surgery for this very reason.

Mike points out in the video that Digital Fabrication has the unique advantage of changing designs in a Computer Aided Design or CAD file. Any changes needed in the product specification are quickly and easily made on the computer and we’re immediately back in production on the factory floor with just a few keystrokes.

To see Mike Davis explain laser micromachining, watch the YouTube video here as the Nation celebrates the contributions of so many talented, dedicated workers on Labor Day!