This week, I had the opportunity to work in the labs with our Director of Operations, Mike Davis. He explained and demonstrated the complete process of production for a customer’s part.

The Process

In the words of Sun Tzu, author of The Art of War, “Every battle is won before it is fought.” This is true because of planning. At Potomac, we follow well-thought procedures, carefully designed for the jobs we execute. These various procedures, like coding, testing and preparing, occur even before the parts begin to run.

Step 1: Proposal

A job starts when a customer reaches out with a problem. The team meets to discuss a plan of action on how to best approach the project. Once a consensus is drawn, the sales department sends out a quote.

Step 2: Creating a Prototype

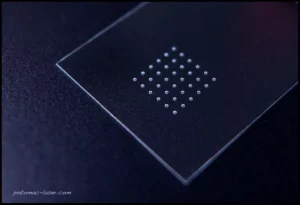

After finalizing everything with the customer, it’s time to begin production. (For the job I observed, the customer requested holes drilled into a delicate glass, and therefore, Davis opted for a UV Laser due to the absorption spectra of the glass).

With a rough drawing of the proposed part, Davis renders adjustments to the customer’s blueprint to fit the scale of the device. He then implements these measurements into a code that supports our lasers.

After developing the program, Davis moves to the lab to begin testing the part. Before running the laser, he adjusts the beam, using a system of lenses and mirrors. The laser runs one sample before Mike sends the prototype for the first article inspection. Quality Control ensures the piece matches the proposal and then full-scale production may begin.

Step 3: Production

When the model finally meets his expectations, Davis grants the next task to a technician, who monitors the laser and troubleshoots, should any unforeseen problems occur.

Step 4: Quality Control and Distribution

Following the manufacturing aspect of the job, Quality Control inspects the parts before distributing them to the customer.

Winning the Battle

The projects completed at Potomac range from medical tools involving cell research, to advanced leak detection devices. With a broad set of capabilities, many jobs may run at once. To successfully manage multiple assignments simultaneously, organization and standard processes must be in practice. Like Sun Tzu said, you must try to win the battle first.

While the customer only sees the final result, the process of manufacturing these devices can be fascinating. Thanks to Mike for allowing us a closer insight of the work done at Potomac Photonics!