Opening DigiFabCon 2014

For the past several years Potomac has participated in DigiFabCon, a digital fabrication conference that highlights how new digital fabrication tools like 3D Printing, CAD design, laser micromachining, and robotics are changing the world. This year, we’ll be presenting a paper with Fab Lab Baltimore at the Community College of Baltimore County [CCBC] on our successful internship program. However, the focus for us is less about technology or machines and much more about how our company changes the lives of students who perhaps would not otherwise have realized they could have a future career in advanced manufacturing.

Changing the World on a Daily Basis

Digital fabrication tools used in manufacturing today are changing the world. Potomac works with inventors, startup founders, manufacturing innovators, and researchers at the leading institutes and universities to solve the challenges next generation products present. On a daily basis we see a wide range of technological breakthroughs that need for us to push the prototyping and manufacturing envelope through laser micromachining, 3D Printing, micro-CNC machining, CAD design, micro-molding, bonding and precision measurement. Here are but a few of the ways we see our work changing the world every day.

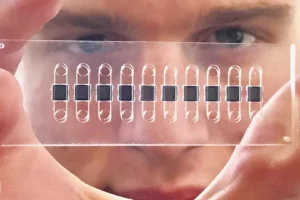

Microfluidics for Point of Care Diagnostics

Microfluidics is a field that is becoming important for fast, economical diagnostics. Requiring just a few drops of blood or other fluid, it is less invasive for the patient and consequently, less painful. Being able to detect disease more quickly also means shorter hospital stays, reducing insurance costs and allowing patients to return to the comfort of their homes sooner.

We have developed a robust rapid prototyping program for new microfluidic devices that yields both low cost and fast turnaround. From there our manufacturing techniques can take a new product from prototype to production quickly and easily.

Whether working with the Israel Institute of Technology [Technion] on antibiotic susceptibility detection via a Lab-on-a-Chip, or the Gerecht Lab in the Dept. of Chemical and Biomolecular Engineering at the Johns Hopkins University Institute for NanoBioTechnology that uses microfluidics to research cancer diagnostics, our advanced manufacturing tools are working to improve life for humanity through microfluidics.

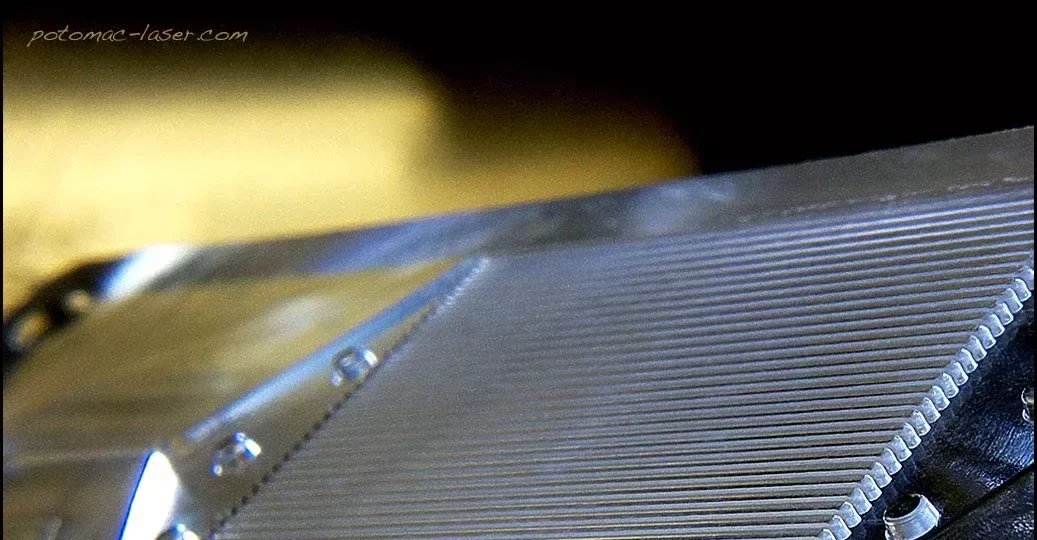

Next Generation Automotive, Aerospace & Electronics Displays

Data overload is not only a problem in email or the Internet of Things. In fact, overwhelming amounts of information being fed into displays make operation of cars, trucks, planes and other tools dangerous for today’s operator. To solve this problem, Potomac is working with manufacturers to develop new types of displays that are invisible to the naked eye when not in use. Request the data, and illumination from behind reveals a series of micro holes to show the specific control, but only when it is needed. Our unique ability to drill holes as small as 1 micron with accuracy and repeatability allow us to rapidly manufacture thousands of holes for Invisible Hole Backlighting, changing how the world gets data while on the go.

Personalized Medicine and New Pharmaceuticals

Microfluidics can also be used to design and fabricate minute quantities of drugs specific to a patient’s needs. Manufacturing devices for Dr. Sagnik Basuray’s group in the Department of Chemical, Biological and Pharmaceutical Engineering at the New Jersey Institute of Technology, we’re able to help move forward research in personalized medicine that increases positive outcomes, while reducing damage to surrounding tissue or organs.

We are excited to share our internship work at CCBC during the upcoming conference. But we feel we are not only teaching STEM job skills as part of the program. Perhaps more importantly, we have been showing students how they can become a part of advanced manufacturing using new digital fabrication tools to change the world!