The coming year promises to see the adoption of technologies that have matured enough to impact a wide range of industries. Here are our predictions for the new capabilities that will be impacting advanced manufacturing and how Potomac and our customers will be leading the way into a new future.

Artificial Intelligence and Machine Learning

Related technologies that have similar but not identical traits, Artificial Intelligence [AI] and Machine Learning [ML] both use algorithms and computation to enhance human skills. While a machine tool operator or 3D Printer technician may see hundreds of scenarios in a period of time, AI and ML can draw from millions of data points to create the optimal process for a specific function.

AI and ML do not stand alone but are integrated into the advanced manufacturing tools that Potomac uses, extending capabilities. For example, AI can monitor processes to ensure that quality parameters are met. Whether we are fabricating microfluidics, medical devices, microelectronics or consumer products, meeting tight specifications are key to successful completion of a job.

In 2020 we predict that AI and ML will have wider acceptance on the factory floor, and our work will integrate these sophisticated tools into more of our laser, CNC, molding, 3D Printing and laser welding machines.

Predictive Analytics

Data collection on the factory floor is only useful if we can synthesize through the large amounts of information and make it useful in our work. Predictive Analytics software allows advanced manufacturers like Potomac to take information from our 3D Printers, laser and CNC micro-machining workstations, laser welders, bonding equipment and other fabrication tools make processes more efficient. Of particular interest to our work is the ability to predict when equipment will need maintenance in order to ensure production is optimal for on-time customer deliveries.

We expect that in 2020 additional predictive analytics software will be on the market. For Potomac this means more up-time that translates to the best customer experience.

High Precision 3D Printing

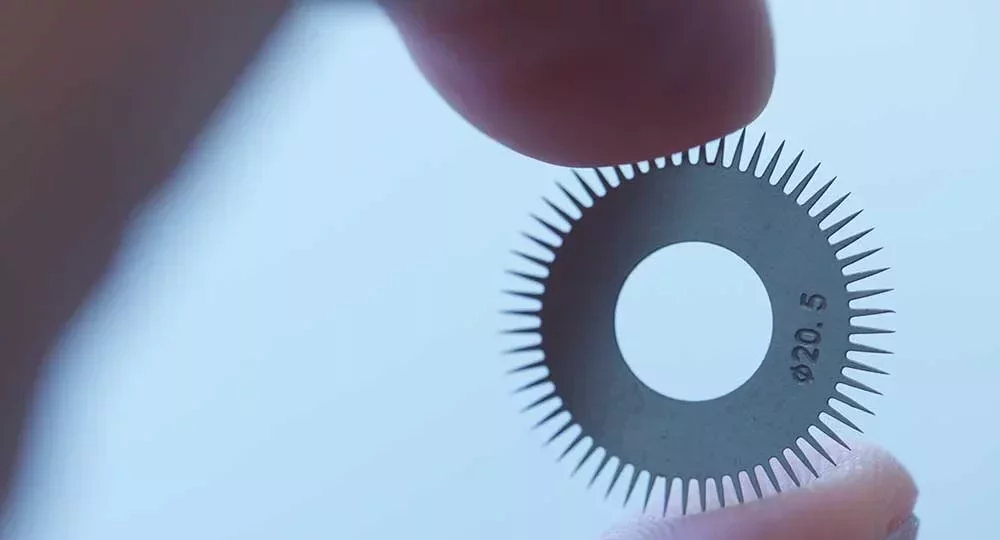

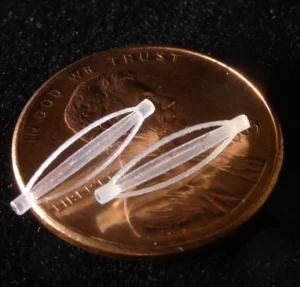

![]()

Potomac has been at the forefront of 3D Printing at high resolution and we will continue to push the boundaries for creating small-scale parts with this emerging technology. 3D Printing can also be a great option for rapid prototyping that can help bring a product to market quickly and economically.

In 2020, our innovative staff will be working to integrate additive manufacturing with our subtractive processes in order to always find the best solution to our customers’ tough fabrication problems.

Automation

Automation and robotics has been in the news for quite awhile and in 2020 we are seeing mainstream industries like retail and warehousing adopting tools that in many ways do the heavy lifting for humans. That said, companies like Potomac will be best able to adopt automation since we have the expert staff to program, monitor, maintain and repair automation machines. In addition, we will be launching a new website with an automated proposal app that will allow customers to instantly get proposals for their projects.

All in all, we predict that 2020 will be an exciting year in technology advances. For companies like Potomac, who are ideally positioned to harness digital transformation, we will be able to continue to lead our customers to success.