Potomac Photonics has developed a toolbox of manufacturing technologies that have made microfluidic device fabrication available to the masses. Our services are the fastest and most cost-effective way to bring your microfluidic devices to the market. The following blog is a summary of a great article published by Technology Networks.

In this age of ever-accelerating technological advancement, scientists’ approach to research has been rejuvenated by the complex array of tests and procedures that are now possible in labs. The introduction of microfluidics and lab-on-a-chip, along with the integration of automation, artificial intelligence (robotics and machine learning) , and data sharing have changed the way scientists perceive of and build experiments . It has also improved the precision of experiments and the reliability of results, while providing vastly improved abilities to analyze and share data. According to Laura Mason , Science Editor for “Technology Networks”, and author of the article, “The Lab of the Future: Artificial Intelligence, Machine Learning, and Microfluidics.”: “To merely say Technology has changed the way we conduct research is an understatement.”

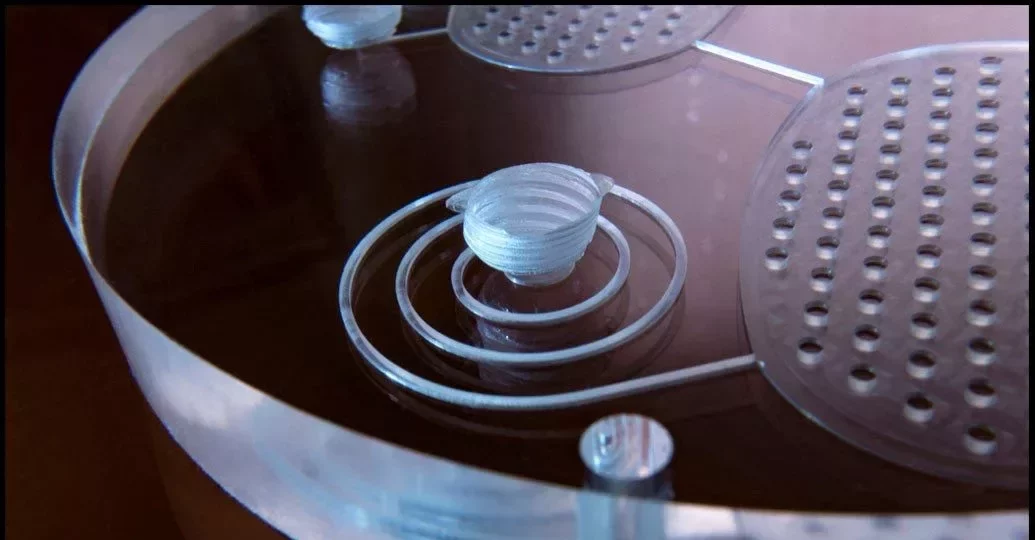

Microfluidics, first implemented for commercial use in inkjet printers, was designed by engineers for the study of organic and synthetic fluids in very small volumes. It enables the manipulation and analysis of liquids in a multichannel system, and is integrated with microchip technology to, in effect, miniaturize biology . According to Mason, scientists are able to do multiple experiments on a chip that can fit into the palm of one’s hand. The portability of a microfluidics lab-on-a-chip, and the smallness of space required to house the experiment is complemented by the small volume of reagents . High resolution analysis that maintain sensitivity, and results that are generated more quickly are also intrinsic, thus lessening the necessity for human intervention,” according to Mason. By working at a small scale, there is also potential for a high throughput, Microfluidic lab-on-a-chip technology is applicable in the areas of genomics, materials science, molecular biology, and organic chemistry. It is also cost-effective.

Robotics has transformed the labor intensive aspect of lab work. We see preprogrammed robotic pipettes replacing traditional Pasteur pipettes. Then followed by robotic blood analysis and testing. One nascent challenge for the successful adaptation of the automated and robotized laboratory is adaptation of the workflow. Workflows must be adapted to encompass a robot’s routine and to process precise microfluidic assays. Workflows should be innovated by and for the scientists who share the laboratory domain with machines.

The resulting volumes of data from these advances also pose a growing challenge in terms of storage and analysis that is its own branch of computer science. One solution for handling the large volumes of data is cloud computing, which is attractive because data is no longer confined to a small isolated physical space, and can be shared and analyzed with collaborators the world over.

Artificial intelligence and machine learning is being deployed to grapple with the “Data Behemoth”. However, as Jim Kelley III, Senior Vice President of Cognitive Solutions and Research for IBM wrote, “The field of artificial intelligence has experienced incredible growth and progress over the past decade. Yet today’s A.I systems, as remarkable as they are, will require new innovations to tackle increasingly difficult real world problems to improve our work and lives. “Currently, artificial intelligence and machine learning allow computers to scrutinize data, and help scientists notice patterns that they might not have found before.

The combination of microfluidics lab-on-a-chip technology, data analysis and sharing, robotics, and artificial intelligence is a potent one, freeing the lab of the future to work more autonomously for scientists, enabling them to focus on life-saving research.

Citation:

1.Mason, Laura Nov. 27, 2017:”The Lab of the Future: Artificial Intelligence, Machine Learning, and Microfluidics.” Retrieved from https://.technologynetworks.com/informatics/articles/the-lab-of-the-future-artificial-intelligence-machine-learning-and-microfluidics-294524

2.Mason, Laura Nov. 27, 2017:”The Lab of the Future: Artificial Intelligence, Machine Learning, and Microfluidics.” Retrieved from https://.technologynetworks.com/informatics/articles/the-lab-of-the-future-artificial-intelligence-machine-learning-and-microfluidics-29452

Please Email [email protected] if you would like partner with us to fabricate your microfluidic device. We utilize a broad range of technologies including lasers, micro-CNC, hot embossing, bonding, welding and more to quickly manufacture custom designs in both prototyping and production quantities.