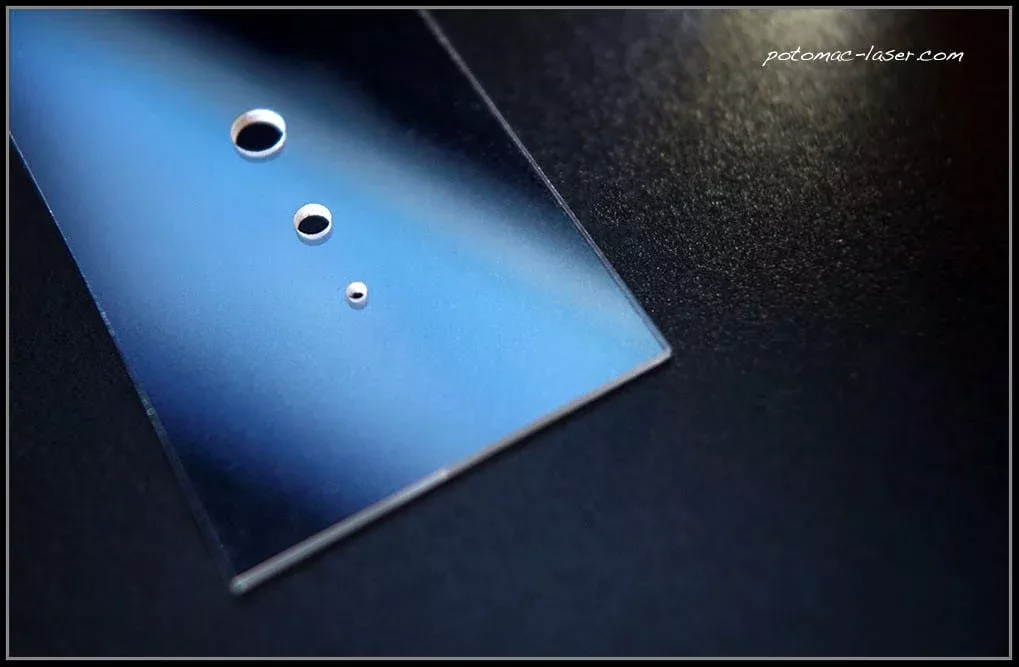

Small holes in microscope slide. Hole diameters in picture are 200um, 500um and 1mm.

Today, a new generation of scientists and engineers, who don’t necessarily work directly in climate change, are actively developing ways to reduce their carbon footprint in the world. Kunal Pandit and Joana Petrescu at the New York Genome Center are examples of these socially conscious world citizens looking to modify their work’s impact on our planet.

Re-purposing Tools of Genome Sequencing

The Illumina HiSeq 2500 has been a workhorse of genome sequencing but like many lab machines, new models were developed to improve performance. What does a research center do with obsolete tools that are no longer supported by the manufacturer?

Kunal and Joana recognized that these big, heavy machines had a lot of good tools inside and watching them go to the waste dump didn’t align with their social consciousness. So, they looked at ways to re-purpose a once valuable tool in one area to an open source platform for microfluidics and imaging.

Creating the 4i Innovation

The team ultimately developed an automated protocol for hi-plex staining and imaging of intact tissue sections using a process called 4i. Kunal and Joana developed an automated protocol for hi-plex staining and imaging of intact tissue sections using iterative indirect immunofluorescence imaging, hence the name.

The New York Genome Center team wrote new code to update the controller, designed a new flow cell that allowed for the imaging of new materials and developed other elements that allowed for building up a multi-plex image.

Potomac Contribution

While the system already had a microscope and microfluidic capability built in, the new design needed something built around the glass slide with precision holes drilled that ensure accurate placement. Holes had to be aligned for the existing system in order to pull a vacuum which was key to the process.

The team had reached out to a number of vendors and according to Kunal, “no one was able to get the placement accurate enough for our needs.” Until they found Potomac. Working iteratively with Potomac design engineers, the tight parameters were achieved.

The substrate was glass and Kunal admitted that even internally they could not measure accurately. Sending the machine’s stage to Potomac, both teams could optimize the design and come up with a repeatable part, NYGC-4.

Potomac’s expertise in metrology is key to working on the small spatial scales needed in genome sequencing, microfluidics, biotech, micro-electronics and more industries miniaturizing products for 21st century markets.