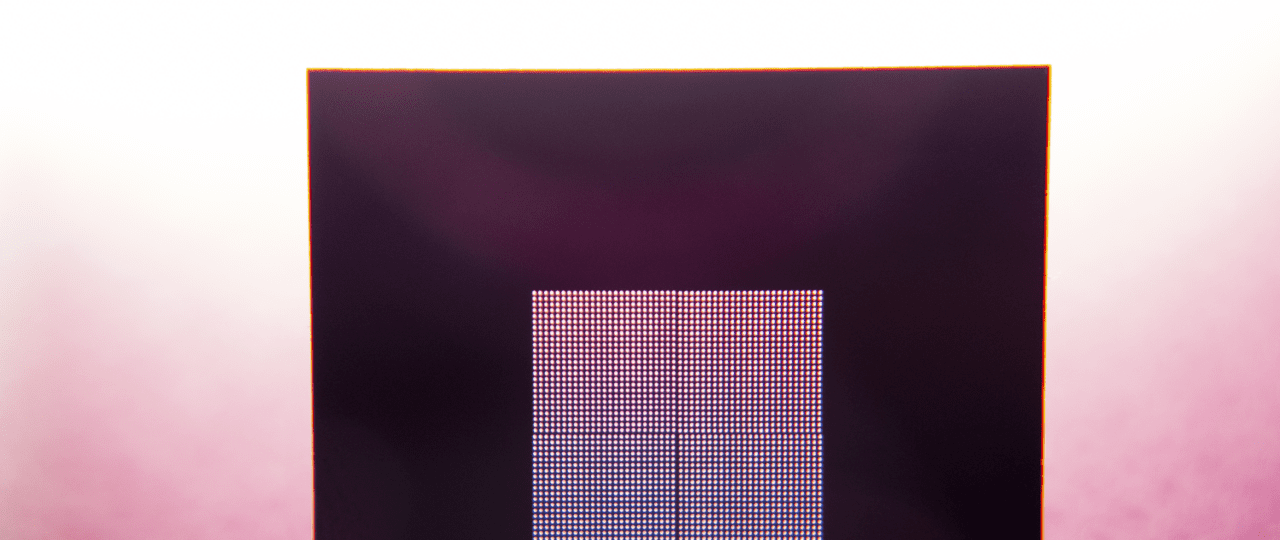

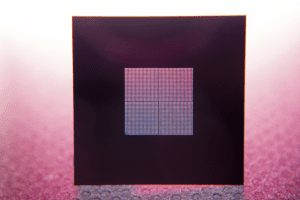

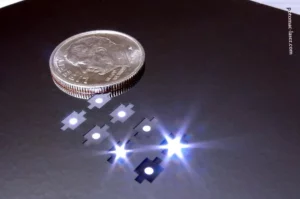

Silicon wafers serve as a fundamental component in various technologies, and Potomac Photonics is leading the charge in their manufacturing and optimization. This industry front-runner has made significant strides in refining techniques for precise feature creation and hole drilling in silicon wafers, which includes wafer dicing and detailed patterning for diverse applications.

Central Role of Silicon Wafers

Silicon wafers are a cornerstone of several industrial sectors, owing to their unique properties and adaptability. They are instrumental in the semiconductor industry, where they form the bedrock for integrated circuits and power electronic devices.

Furthermore, in the healthcare industry, silicon wafers are utilized for the creation of advanced biosensors and microfabrication tools. The automotive and aerospace sectors have also leveraged silicon wafer technology, contributing to the development of sophisticated sensors and control systems.

However, the application of silicon wafers in the field of microfluidics is a remarkable intersection of innovation and technology.

Silicon Wafers and Microfluidics

Microfluidics is a science that manipulates and controls fluids that are geometrically constrained to a sub-millimeter scale. It has broad implications across several domains like drug discovery, molecular biology, and point-of-care diagnostics.

Potomac Photonics’ refined techniques in silicon wafer technology have allowed for the development of high-precision microfluidic devices. The company’s advanced methods for dicing and patterning silicon wafers result in microfluidic devices that provide superior fluid control capabilities.

From Concept to Production

One of Potomac Photonics’ significant capabilities lies in its ability to take a project from the initial prototyping stage to full-scale production. Through iterative design refinement and meticulous manufacturing processes, Potomac effectively transitions from prototype to mass production, delivering high-quality silicon wafers.

Silicon Wafers: Future Perspectives

The future applications of silicon wafers are vast and varied. With the rise of the Internet of Things (IoT), the demand for small-scale electronics and sensors, which heavily rely on silicon wafers, is expected to surge. Concurrently, as we progress deeper into precision medicine and genomics, microfluidic devices developed from silicon wafers will play an increasingly vital role.

Potomac Photonics, with its cutting-edge manufacturing technologies and dedication to precision and scalability, is well-positioned to remain at the forefront of silicon wafer advancements. As we delve deeper into this technological era, Potomac’s role in shaping the future of silicon wafers cannot be overstated.