Potomac Photonics is pleased to announce the purchase of a new Coherent excimer laser for its contract laser micromachining unit. This laser, which is suitable for rapid prototyping and production of miniature parts, will be integrated on a system capable of machining flat and 3D parts.

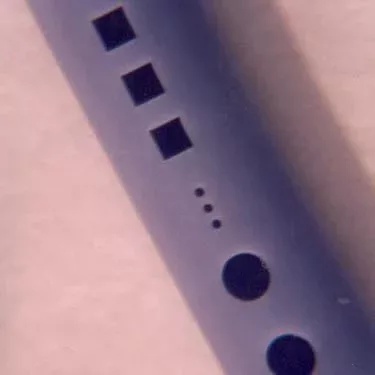

Excimer lasers emit concentrated light within the ultraviolet (UV) region of the spectrum and are especially suited to machine complex features in polymer and glass material. Microhole drilling, precision cutting, and etching are among the many applications for which this laser will be used. With the ability to achieve features as small as 2 microns, customers in various industries such as medical, biotech and electronics will be able to Email their drawings to Potomac and have their parts made quickly and cost-effectively.

Fabrication utilizing excimer lasers is often referred to as a cold process because the heat- affected zone is very localized and there is little to no apparent thermal damage on the surface. This characteristic is important for customers who want to minimize debris and want to limit costly time consuming secondary cleaning processes.

“While Potomac is already an established leader in the use of excimer laser technology, this expansion of our production resources will greatly enhance our ability to provide extremely quick turnaround times for our customers,” stated Mike Davis, Director of Operations, Potomac Photonics.

“The investment in this laser is consistent with our strategy to continually upgrade and expand our manufacturing capabilities in order to provide our customers with the best laser fabrication solutions on the market” added Mike Adelstein, V.P of Potomac Photonics.