Potomac Photonics has been collaborating with our friends at NASA for years. In fact, it was a set of Small Business Innovation Research contracts with NASA’s Marshall Space Flight Center back in the mid-1990s that was instrumental in putting our company at the forefront of the micromachining industry.

While Potomac has grown exponentially since those early days, these collaborations are always very exciting projects that push us to perform at the highest level. Thus it was very fulfilling to see this article in NASA’s Spinoff publication profiling our work to develop technologies such as lasers and ultrasensitive detectors for NASA and other agencies, including the Department of Defense and the National Science Foundation.

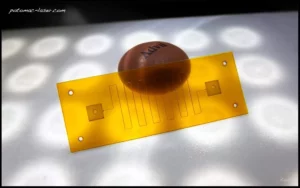

As described in the article, our latest project with NASA had two main objectives. The first was to “prove the capability of excimer lasers in crafting intricate, diffractive optical elements—lenses etched with thin, micro-structure patterns that manipulate the light passing through them.” The second was “to develop an integrated computerized workstation capable of mass-producing such optical components.”

We knew that to be able to manufacture these small-scale parts on a larger scale would be incredibly useful—they have myriad applications, from fiber optics to information storage—but the available methods at the time were not only prohibitively expensive but extremely time-consuming. “NASA certainly was interested (in advancing the technology), because they do a lot of work with lasers and light,” said Potomac Photonics President Mike Adelstein.

Our central innovation—to use AutoCAD software to digitally control the process—afforded a faster, cheaper and significantly more flexible means of production: a major victory for both the company and the industry. “The work with NASA showed a different way of making these components and pushed the limits of the technology. It really set the tone for our direction in leading this field,” stated Adelstein in the article.

Potomac Photonics continues to supply parts and services to NASA, and to collaborate with NASA-formed entities such as the Center for Research and Exploration in Space Science and Technology (CRESST). After working with us on the ASTRO-H satellite project—in which we inscribed laser markings on filter carriers for imaging systems, with 24-hour turnaround—CRESST research scientist Meng Chiao praised the quality and the exclusive nature of our work, stating “To my knowledge, they’re the only company with this laser marking system and with precision placement capability.”

In addition to Potomac’s projects with NASA, the Spinoff article also highlights some prominent recent projects we’ve done with John Hopkins Medical Center, including innovations for localized cancer treatment and a device to fight cervical cancer.

All of these projects really speak to the core philosophy here at Potomac, and underscore our mission. In the words of Mike Adelstein: “The ability to machine parts like this that are so small—it’s going to be life-changing.

Read the full article at spinoff.nasa.gov.