Optimizing Microfluidic Mixing of Viscous Fluids

A deep understanding of underlying microfluidic technology sets advanced contract manufacturing companies apart in serving the industry. Companies may buy digital fabrication tools to manufacture customer-specified designs, but it is a partner that comprehensively and experientially understands the rigors underlying microfluidics technology that can innovate processes to improve customer device designs and help take optimized products to market.

Innovation at Potomac centers around our commitment to go beyond the simple fabrication of microfluidic chips to developing the processes that take products to the highest performance levels. One of our recent innovations does just that by optimizing the mixing of viscous fluids in microfluidic devices.

Innovating Customized Microfluidic Mixers

Through our work meeting demanding customer device specifications, Potomac recognized that mixing viscous liquids is difficult for laminar flow processes in microfluidic devices. The ability to mix liquids is especially important since many applications require blood samples, which can be quite viscous. While mixers are commercially available, lack of customization capabilities limits a new product’s ability to be optimized for specific applications, reducing market success.

Through our work meeting demanding customer device specifications, Potomac recognized that mixing viscous liquids is difficult for laminar flow processes in microfluidic devices. The ability to mix liquids is especially important since many applications require blood samples, which can be quite viscous. While mixers are commercially available, lack of customization capabilities limits a new product’s ability to be optimized for specific applications, reducing market success.

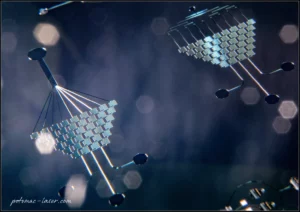

With funding from the National Science Foundation’s SBIR program, Potomac’s R&D team set upon developing novel microfluidic mixing technology that could be tailored to new biotech, environmental, and healthcare products during the prototyping phase. The concept is to combine Hydro-dynamic Flow Focusing [HDFF] with micro-structures to disrupt the fluid as it flows in a chip’s channels.

HDFF is a way to manipulate the mixing profile of multiple liquids allowing for precision control of the concentration. More viscous fluids present challenges in the mixing process, reducing accuracy of test results. However, complex geometries within microfluidic device channels can disrupt flow to improve uniformity of the sample’s concentration.

Potomac’s Innovation

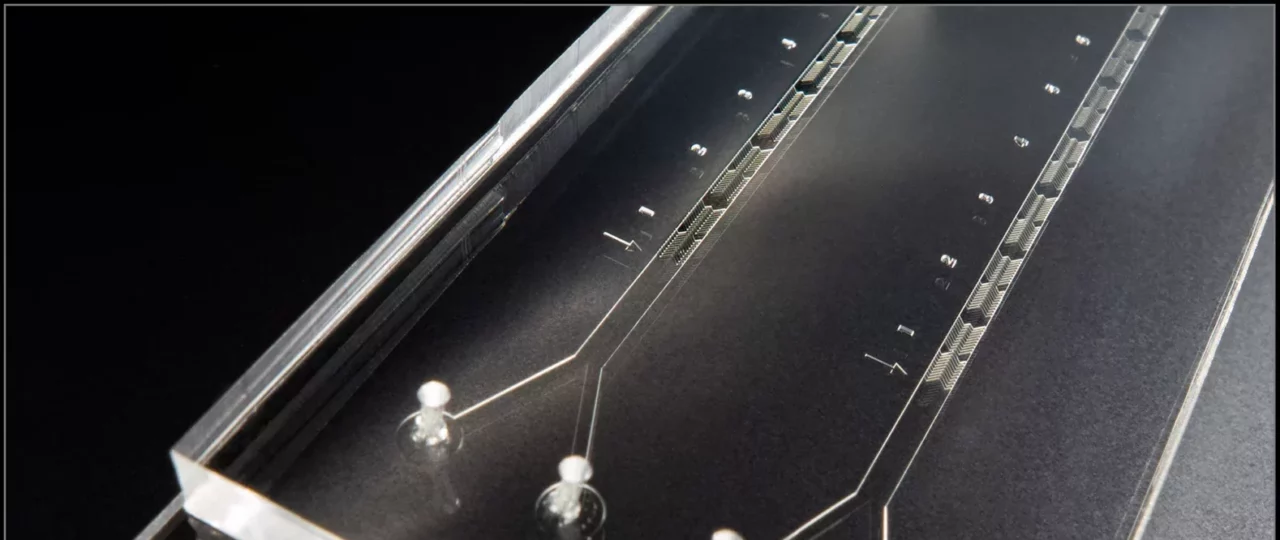

Utilizing a herringbone pattern of 50-micron structures, Potomac has successfully demonstrated mixing of viscous fluidics in microfluidic channels of approximately 100 microns in height. The structures create chaotic advection, a phenomenon of diffusive mixing, that results in faster and more thorough blending of fluid constituents.

Potomac R&D Scientist Abhay Andar explains that the project has demonstrated the number of herringbone structure sets that are optimal for specific applications. Utilizing digital fabrication processes that can be modified in computer aided design [CAD] software, it is fast and easy to adjust the manufacture of structures to meet changing application needs.

Next Steps

Potomac’s innovative microfluidic device fabrication techniques allow for customization in the rapid prototyping phase of new product development. Next, automation and other methodologies will scale the novel on-chip mixers to high volume production quantities with corresponding reduced cost and fast delivery.

Increasingly available point-of-care diagnostic applications that utilize highly viscous fluids like blood demand innovations like the Potomac Microfluidic On-chip Mixer in order to capture mainstream markets and save lives.