Speed is at the center of today’s world, especially as biotech, medical device, microelectronics and consumer products companies vie to get new innovations to market ahead of their competition. From rapid prototyping and iterative process development to high volume manufacturing, quick parts fabrication is essential every step of the way.

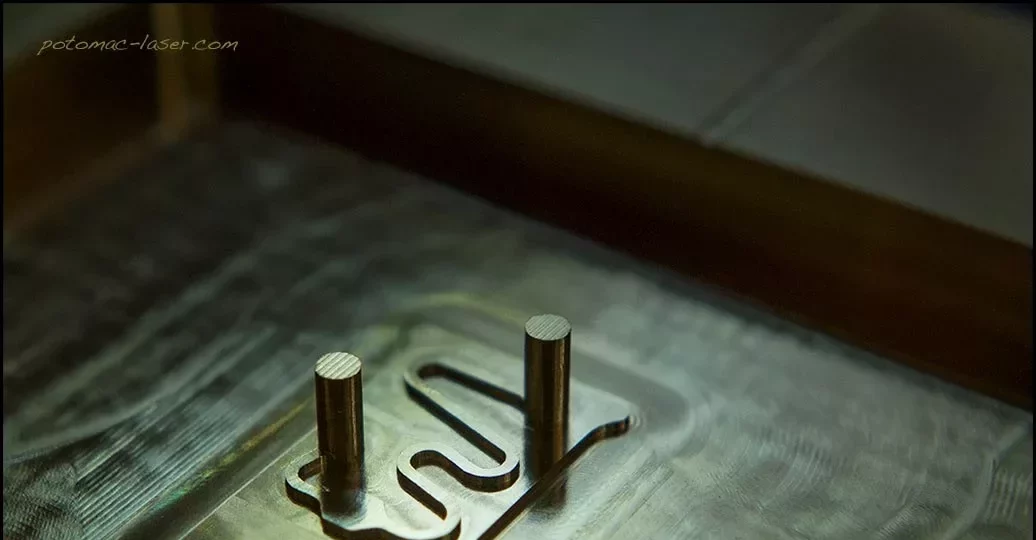

Looking to exponentially accelerate our customer experience, Potomac turned to the automation by adding a new micro CNC milling machine to its suite of manufacturing technologies. Many stories in the press today focus on the impact automation and robotics is having on the workforce. However, repetitive tasks are best executed by fast, accurate machines, while humans focus on functions that require high-level cognitive ability. Adding a new micro CNC milling machine has freed Potomac staff to optimize CAD designs, monitor processes, and ensure the highest quality control. In the meantime, the cnc milling system expedites time-consuming jobs like changing drill bits to ensure rapid turnaround.

Potomac President and CEO Mike Adelstein explains, “The micro CNC Milling machine is a totally new platform to manufacture small parts. With the ability to get down to spot sizes as small as 50 microns, this tool approaches the accuracy and precision of laser micromachining with the speed and expanded material possibilities of traditional CNC. Potomac always has the right tool for a specific job and with ultraviolet laser micromachining and automated CNC milling machining we can fulfill most advanced manufacturing needs in a one-stop shop.”

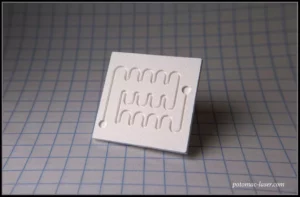

Add laser welding, 3D Printing, micro-molding, SU-8 Photolithography and more to these subtractive manufacturing processes and Potomac can make just about anything you need to get your product to market fast. Our specialties include microfluidic device manufacturing for Lab-On-A-Chip, Organ-On-A-Chip and development of other innovative biotech products.

Contact us today to explore the options that can speed your product to market with higher possibilities of success.