Today, speed is the name of the game. But speed without accuracy in all its forms defeats the purpose of fast delivery. At Potomac, we provide some of the quickest turnaround in manufacturing for medical device, microfluidic, biotech, consumer product and microelectronics customers also with the highest level of quality.

Today, speed is the name of the game. But speed without accuracy in all its forms defeats the purpose of fast delivery. At Potomac, we provide some of the quickest turnaround in manufacturing for medical device, microfluidic, biotech, consumer product and microelectronics customers also with the highest level of quality.

Meeting customer specifications is especially challenging when we are working on very small spatial scales. Laser or CNC drilled holes of a few microns in diameter with ½ micron accuracy need extra precise measurement to ensure our advanced manufacturing services provide fully functional parts for the sophisticated products our capabilities enable.

Striking a balance between fast delivery and accuracy is the QC holy grail at these super small sizes. Potomac has developed internal automated inspection software that significantly increases measurement speed by calculating the size of multiple holes simultaneously. At the moment, 5 holes can be verified in as little as 30 seconds which exponentially speeds up inspection.

Open Source Innovation

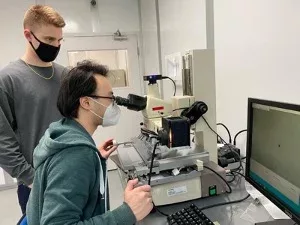

The project points to the successful innovation of today’s young people. College students Clay Chung and Jacob Adelstein worked as interns at Potomac for the past year while the pandemic curtailed normal college life. “We always give our interns real-life projects”, explains Potomac President and CEO Mike Adelstein, “that would reinforce what they were learning from books and create the opportunity for creative problem-solving.” In addition, the real-world project would supplement online virtual classes for a more well-rounded experience.

Drawing from the open source ImageJ, a Java image processing program originally developed at the National Institutes of Health, Clay and Jacob used developer tools available to the community to create their own version of the analysis tool. The new software can quickly capture and image a part in order to isolate and calculate the size of holes.

Because the interns were developing the software for an industrial application, they recognized some important parameters. “We wanted the program to be easy to set up as Potomac jobs change from customer to customer”, says Jacob. “It’s very user friendly which is important in a contract manufacturing environment.” Clay reiterates: “Costs were a consideration since that ultimately impacts customer pricing. We were able to use off the shelf equipment that allowed us to meet our cost goals and provide high level QC that was also affordable.”

The process works with most materials, but there needs to be good contrast for the imaging to pick up the required level of hole detail. Kapton, mylar, and metals are good candidates, while clear materials are more difficult to image. An added advantage is the ability to get a clearer idea of edge and cut quality which for many applications is a key consideration of good quality.

The calibration process works from standards developed with the customer’s own measurements and the interns plan to focus next on further improving both calibration and ease of use. Of course, the new automated inspection software works best with smaller hole sizes since the entire hole needs to be seen by the system for successful imaging.

Thanks to our powerful internship program, Potomac has exponentially extended the industry standard in quality assurance while maintaining fast delivery.