Every day, disruptive technologies allow humans to enter a new world that brings innovations to life. Whether battling climate change by reducing the amount of fossil fuel burning, helping autonomous vehicles navigate roads, guiding man to Mars, or cleaning up toxic waste, technology innovations are the key to solving our world’s problem’s – today and into the future.

The Role of Light in 21st Century Innovations

Electricity has been a driver in high tech products for decades but today light is gaining ground as the electro-magnetic medium that devices access for power and communication. The unique properties of laser light, in particular wavelength and coherence, increase speed, accuracy, and precision of new technologies.

Communication is a case in point. Transmitting light increases not just speed but also data quality. But how do we take light and make it useable in practical applications?

Shadow Masks to Enable Light Technologies

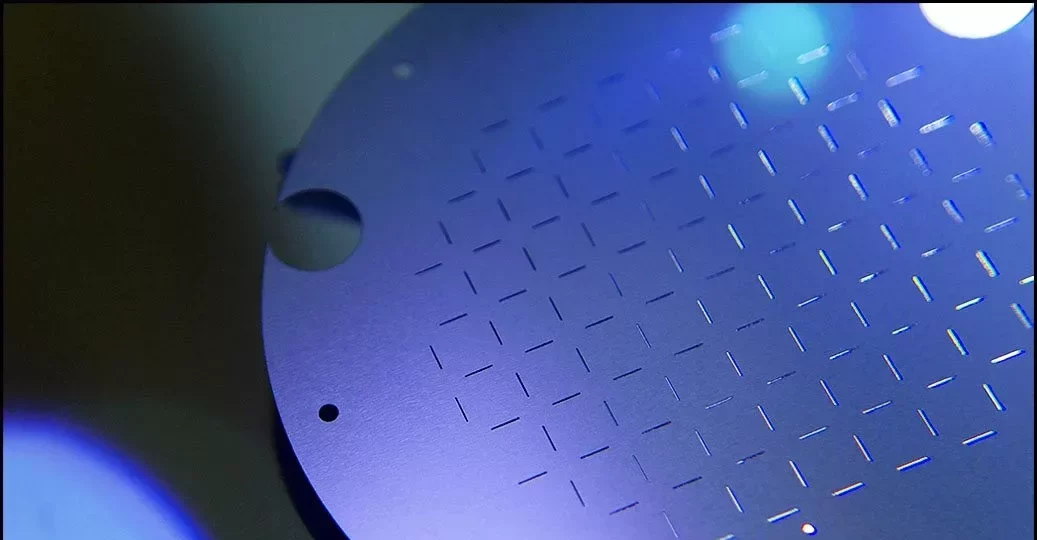

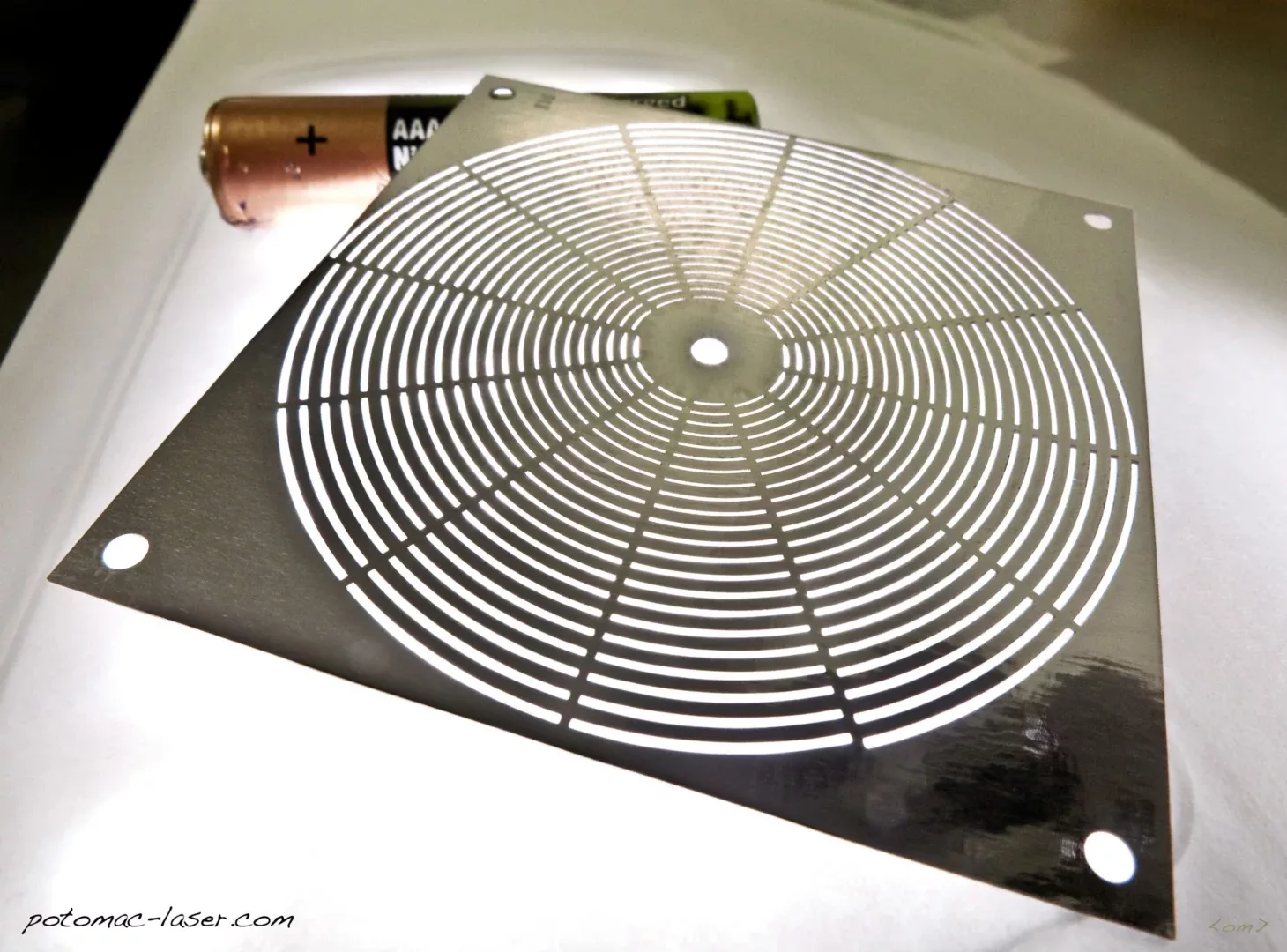

For many applications shadow masks serve a vital role in guiding light with high precision to an exact location through a stencil. Potomac’s ability to digitally fabricate holes as small as one micron translates to shadow mask features with super high resolution for today’s increasingly miniaturized products.

As with all digital manufacturing, shadow mask patterns are created in Computer Aided Design software commonly called CAD. The ability to digitally instruct the laser or CNC cutting tool means that changes can be quickly and easily implemented right from the computer. This is an important feature when rapid prototyping new products since we can iterate a design for customer testing so that speed to market is exponentially accelerated.

Shadow masks are manufactured in a wide range of materials, but most often metals are the substrate of choice. Potomac’s extensive capabilities allow customers to choose stainless steel, tungsten, or tantalum for their parts. Some applications require organic polymers such as polyimide, which can be laser micro-machined without thermal damage creating flawless parts. Our ability to be able to choose the right tool for the exact material produces shadow masks that meet demanding precision requirements.

Manufacturing at the Speed of Light

Potomac brings decades of experience manufacturing high precision parts such as shadow masks at record speeds. Our advanced factory floor is optimized to automate production without sacrificing quality creating the fastest turnaround time in the industry. We have even automated quality inspection so that the parts a customer receives fully meet spec time after time.