Advanced manufacturing services involve more than just feeding CAD files into a 3D Printer, laser micromachining workstation or micro CNC machine. To best service our customers in the biotech, medical device and microfluidics industries, Potomac has had to stay at the leading edge of new technologies, pushing the digital fabrication envelope through internal R&D programs. Our internal research has yielded best practices, creative implementation of standard processes and solutions to vexing manufacturing problems.

A new section of the Potomac website, R&D Notebook, sheds light on our behind the scenes work that fosters innovation in novel applications. Here we’ll share the background of a new technology or process, how it applies to specific applications and where it might fit into your own R&D, prototyping or production runs.

Our first R&D Notebook entry discusses the work Potomac has invested in multi-layer microfluidic device fabrication. Perhaps the greatest challenge associated with microfluidic device manufacturing is the required expertise in engineering, physics, biology, medicine, chemistry, and biotech. As in any hot, new tech area, time to market is key to product success. With digital fabrication processing that utilizes easily modified Computer-Aided-Design [CAD] software, biotech and medical device companies can rapid prototype to test design concept and iterate changes quickly and inexpensively. The resulting final product is the best in its class and ready to dominate any market!

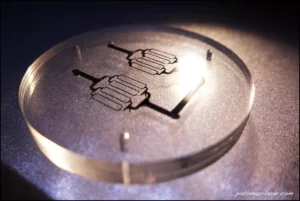

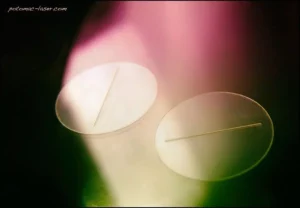

Potomac has worked on microfluidic device fabrication technology by combining laser micromachining of channels as narrow as 10 microns, high precision alignment, sophisticated bonding techniques, inexpensive replication, and laser via hole drilling. We can also incorporate 3D Printing technology or micro CNC machining where required.

With Potomac’s R&D programs you can be assured our advanced manufacturing programs are state of the art. Check out our inaugural R&D Notebook post on multi-layer microfluidic device fabrication here (https://www.potomac-laser.com/services/applications/microfluidics-pressure-sensitive-adhesives/) and watch this space for updates on other, equally exciting, manufacturing process developments.