Microfluidics is an evolving technology that enables scientists and engineers to perform molecular biology including DNA and RNA sequencing, PCR, and even whole transcriptome analysis more rapidly and at a lower cost than conventional technologies. Microfluidics technology leverages the manufacturing processes long utilized for the manufacturing of semiconductor (IC) chips to achieve the production, at high volumes of highly engineered devices capable of performing the chemical and biological reactions, separations, and purification operations required for molecular biology projects. By enabling the miniaturization of these complex operations, experiments normally conducted at the scale of liters can now be performed at the scale of microliters or less, a reduction in volume of 6 orders of magnitude! Miniaturization clearly reduces volumes of costly reagents, but it also enables for designs that eliminate the performance limitations of conventional equipment such as shake flasks and microtiter wells. A good example of this is the standard PCR process for DNA replication which entails performing a series of reaction, heating, cooling, and mixing operations. Because of equipment size and characteristic mixing lengths on the order of centimeters; heating and cooling operations limit the throughput. On the other hand, microfluidics with characteristic mixing lengths on the order of micrometers reduce heating and cooling times to seconds from minutes, resulting in a

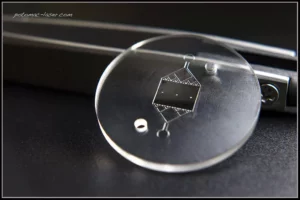

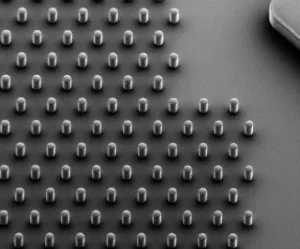

significantly higher throughput for the microfluidic device over the shake flask. Another aspect of microfluidic devices is their flexibility. Remarkably, using only a few fundamental geometrical shapes such as pillars, channels, holes and wells individually or in combination, it is possible to design a variety of reaction, separation and purification operations, making this unique technology amenable to both synthetic and modular design strategies. Designs can be easily customized during prototyping to achieve process objectives such as throughput and purity. Finally, production of microfluidic devices can leverage economies of scale by integrating high-throughput replication and bonding technologies such as hot embossing and micro-injection molding with thermal and laser bonding technologies.

Potomac Photonics’ Product & Process Technology team has the expertise to help you throughout the entire product development lifecycle. We will work with you to develop a customized project plan from design concept and prototyping through scale-up and high- volume manufacturing. Potomac microfluidic and microfabrication experts can even advise you on the design of a microfluidic chip customized for your application and will develop a detailed cost model that will enable you to predict how your unit costs will change as your production requirements increase.

.