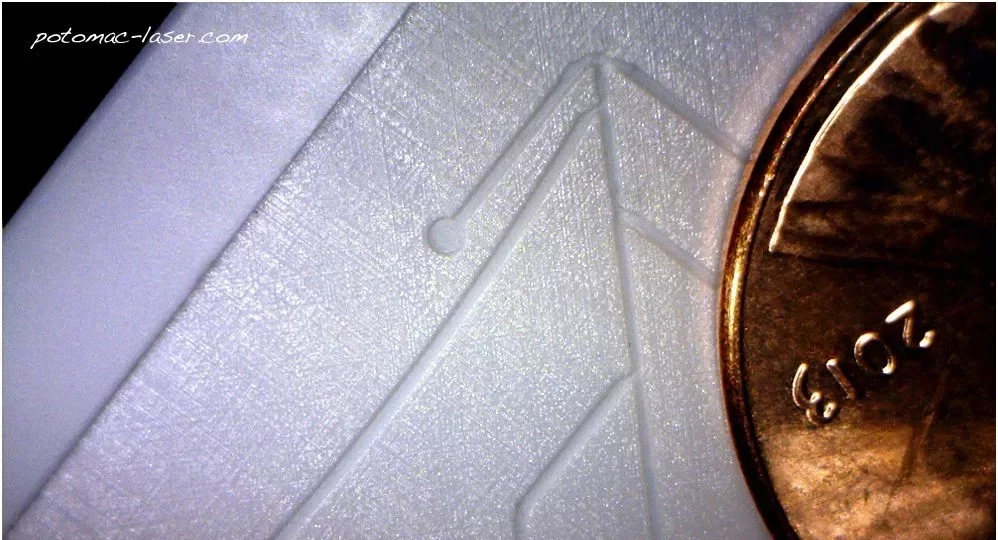

We recently completed a project in which a customer required very precise micro channels in Polystyrene. Polystyrene can be a difficult material to laser machine, as the thermal effects of the process are often greater than are seen with other polymers, such as Polyimide and PEEK. After evaluating various manufacturing options, we chose to machine a master that was the inverse of their design and mold the channels in polystyrene. This process produced extremely accurate parts without any of the thermal effects that are seen when laser machining this material. This molding process is also very fast and provides scalability to high volume production. In addition, the process has the capability to replicate features as small as 5 microns in difficult to machine materials such as Cyclic Olifin Copolymers.

One of the greatest challenges in fabricating small features in polymer materials is selecting the most appropriate manufacturing technology. Depending on the end users’ requirements, factors such as size, cut quality, and design complexity are all critical areas to consider when evaluating which process will yield the desired results. At Potomac, we have developed multiple processes, allowing us to offer the broadest range of solutions for applications that require micro holes, channels, and other types of miniature features. The types of manufacturing technologies used include Excimer and Solid State UV lasers, Hot Embossing, Micro-CNC, and even 3D printing. www.potomac-laser.com