A program focused on creating a robust partnership with universities in order to develop new products and manufacturing technologies.

The Potomac’s Education Manufacturing Initiative is a low cost program that enables students, faculty and researchers develop and build their micro devices. We completed many projects including:

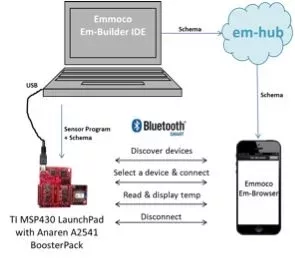

University of Maryland Baltimore County (UMBC): An internship with Aidan Gray focused on creating a network of wireless sensor nodes that communicate with mobile devices (smartphones and tablets) to send and receive sensor data from devices fabricated by Potomac Mesosystems and Potomac Photonics.

Boston University: Potomac Photonics fabricated precision stencils to pattern seeded stem cells such that cells are grown in a defined arrangement relative to each other. By preparing various stencils, the BU researchers hope to determine how the relative position of stem cells affect their differentiation efficiency and differentiated progeny. Click here for more information: https://www.potomac-laser.com/blog/potomac-photonics-supports-bus-stem-cell-research-with-3d-printed-parts/

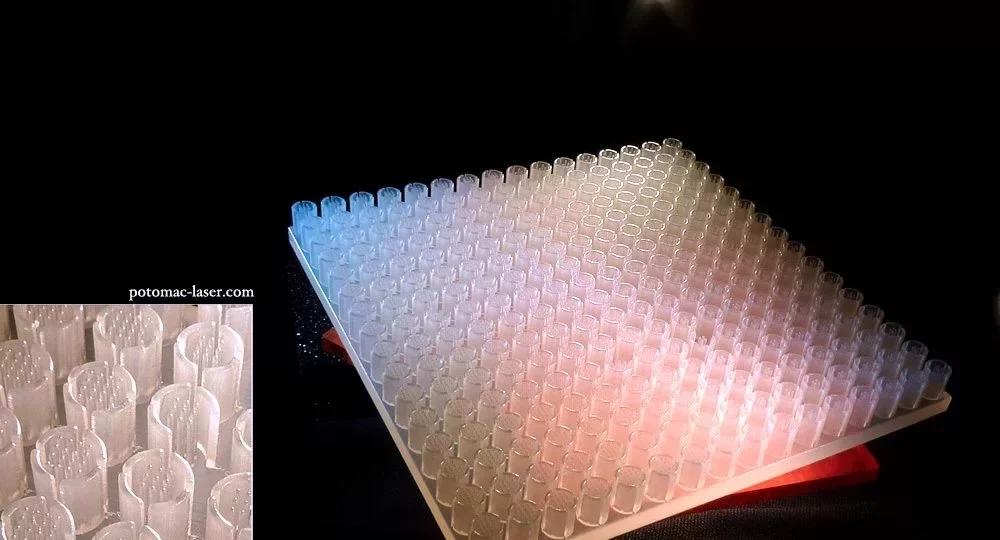

University of Colorado, Boulder: Potomac Photonics has recently fabricated micro-parts to be used on a project to develop new techniques for diagnosing and treating gastrointestinal diseases. Utilizing advanced precision micromanufacturing technologies, Potomac drilled over 80,000 blind holes in a polymer material. These holes were about 70 microns deep and had diameters between 110 and 140 microns. Click here for more information: https://www.potomac-laser.com/blog/potomac-photonics-helps-prototype-robotic-capsule-endoscope/

Leading universities and colleges around the world work with us to fabricate innovations of all kinds. If you’re a student, graduate assistant, or faculty member, we’d love to talk with you about how we can work together to advance your next project with our outstanding facilities and expert technicians.