Welcome to the inaugural post of our “Material Spotlight” blog series, where we delve into the unique materials available through Goodfellow and explore how Potomac Photonics’ advanced micromachining services can enhance their applications. Today, we focus on thin metal foils—versatile materials that play critical roles in various industries.

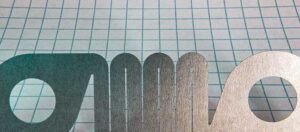

Goodfellow is renowned for its extensive catalog of high-quality materials, including a wide range of ultra thin metal foils. Among their offerings, Aluminum Foil stands out for its excellent thermal and electrical conductivity, lightweight nature, and high reflectivity, making it ideal for applications such as packaging, insulation, and electronics. Copper Foils from Goodfellow are highly conductive and ductile, essential for applications like electronics shielding, battery electrodes, and printed circuit boards. Nickel Foils are prized for their ductility and high melting point, finding uses in electromagnetic shielding and chemical production. Meanwhile, Titanium Foils, known for their high strength-to-weight ratio and exceptional corrosion resistance, are indispensable in aerospace, medical devices, and high-performance engineering applications.

Goodfellow is renowned for its extensive catalog of high-quality materials, including a wide range of ultra thin metal foils. Among their offerings, Aluminum Foil stands out for its excellent thermal and electrical conductivity, lightweight nature, and high reflectivity, making it ideal for applications such as packaging, insulation, and electronics. Copper Foils from Goodfellow are highly conductive and ductile, essential for applications like electronics shielding, battery electrodes, and printed circuit boards. Nickel Foils are prized for their ductility and high melting point, finding uses in electromagnetic shielding and chemical production. Meanwhile, Titanium Foils, known for their high strength-to-weight ratio and exceptional corrosion resistance, are indispensable in aerospace, medical devices, and high-performance engineering applications.

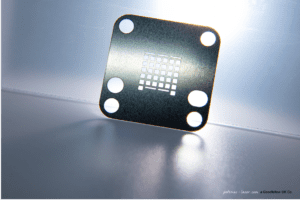

At Potomac Photonics, we specialize in precision micromachining, enabling us to create intricate features in these thin metal foils with unparalleled accuracy. Our micro-cutting services achieve feature sizes as small as 1 micrometer, while our micro-drilling capabilities allow for the creation of high-density hole arrays. We also offer precision micro-milling for detailed 3D structures and laser ablation for selective material removal, ensuring we can meet the specific needs of our clients across various applications.

A recent development in the field of thin foils highlights the cutting-edge applications and advancements. Researchers have made significant progress in laser-based manufacturing for battery production, utilizing high-speed laser cutting of ultra-thin aluminum and copper foils. This method, crucial for the e-mobility sector, deals with stringent constraints like highly reflective materials and very low thicknesses, showcasing the technological advancements in processing these materials efficiently and with high quality (AIP Publications). To meet the growing demand, Potomac Photonics has recently increased its capacity to laser cut ultra thin metal foils, specifically targeting applications such as electric vehicle batteries and other high-precision industries.

The collaboration between Potomac Photonics and Goodfellow brings together high-quality materials and cutting-edge micromachining capabilities, offering significant advantages to industries such as electronics, medical devices, aerospace, automotive, and energy. For instance, flexible electronics benefit from our precision micromachining of copper and aluminum foils, while the medical industry relies on our ability to create biocompatible implants and diagnostic tools from titanium and stainless steel foils.

The collaboration between Potomac Photonics and Goodfellow brings together high-quality materials and cutting-edge micromachining capabilities, offering significant advantages to industries such as electronics, medical devices, aerospace, automotive, and energy. For instance, flexible electronics benefit from our precision micromachining of copper and aluminum foils, while the medical industry relies on our ability to create biocompatible implants and diagnostic tools from titanium and stainless steel foils.

Submitting a request for a quote is seamless with our one-stop shop solution. By visiting Potomac Photonics, you can easily upload your design drawings and specifications, ensuring a rapid response and detailed quote. Additionally, you can explore Goodfellow’s extensive catalog of thin metals at Goodfellow, allowing you to find the perfect material for your needs and submit an inquiry for a swift and informative response.

Both Potomac Photonics and Goodfellow are dedicated to delivering exceptional service and top-notch quality. Our commitment to rapid turnaround, excellent quality, and responsiveness ensures that you receive the best possible outcome for your projects. Partnering with us provides you with an efficient, customer-focused experience that supports your innovation and success. Visit our websites today to get started on your next project!