Potomac is fortunate to be located in Maryland, which is one of the nation’s leading areas for BioTech research and development. With highly regarded medical schools at the University of Maryland and Johns Hopkins in Baltimore, and the National Institutes of Health and Walter Reed Hospital in Bethesda, the Craig Venter Institute in Rockville, as well as bioengineering laboratories at UMBC and UMCP and a large number of commercial BioTech companies, there is an unparalleled concentration of the best and the brightest in the field, all within a short distance of our facility.

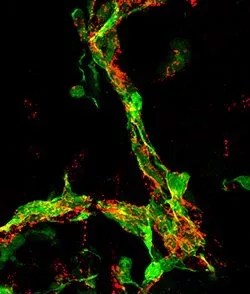

One of the most intriguing BioTech programs, both from the standpoint of saving lives and collaboration in our Digital Fabrication work, is Stem Cell Research. And the leading Stem Cell research group is right here in Baltimore at the University of Maryland Center for Stem Cell Biology & Regenerative Medicine [UM-CSCBRM].

The central mission of UM-CSCBRM is to bridge the gap from basic stem cell science to on-site clinical investigation of stem cell treatments in human diseases. By understanding the inner mechanics of how stem cells work, the Center promises to “make breakthroughs that will enable us to diagnose diseases earlier, cure them more effectively, and someday prevent them”.

The Stem Cell Center’s Director, Dr. Curt Civin, explains why he was excited to work in the field: “Basic science questions in stem cell research can translate immediately into diagnosis, therapy, and eventually prevention – as a physician scientist I couldn’t resist getting into STEM cell research.” Dr. Civin has a particular interest in pediatric patients and has been instrumental in saving the lives of many children through his groundbreaking work on stem cells in the blood.

A major requirement for advancing the field into treatment is the availability of stem cells. Stem cells are challenging to grow in the lab as compared to other types of cells so that availability is limited. Further, cells that are modified can provide scientists with models for many different diseases and these take the longest to produce. Discovery of cures to many human conditions, as well as future prevention can only happen when researchers have the cell lines they need to carry on their work. Thus, a major thrust of the Center is the production and storing of stem cells for researchers around the world.

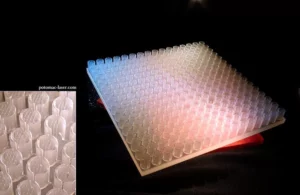

Specialized tools are needed at this level of new research. Combining laser micromachining with 3D Printing and other fabrication technologies, Potomac has used our Education Manufacturing Initiative to help support researchers in stem cell research.

For Boston University, Potomac was able to fabricate controlled-cell microenvironments in order to manage and measure how the cells interact with each other. Using a 3D Systems ProJet high resolution printer, we were able to create stencils on which seeded stem cells could be grown in a specific arrangement. The results will hopefully show how relative position and proximity of stem cells to each other affect their differentiation efficiency and resulting differentiated progeny.

We, at Potomac, especially love our work when we can be at the forefront of the BioTech revolution, helping to save lives and re-fashion the future of medicine.