The world today seems consumed with fears about Artificial Intelligence, otherwise known as AI. Writers, journalists, ad copywriters, teachers, and artists are fearful their jobs will be lost to computers but in manufacturing we have been applying a subset of AI to manufacturing for decades with positive results.

Like other forms of AI, Machine Learning or ML gathers large amounts of data and analyzes the information to make informed decisions about various aspects of the manufacturing process. Computation draws from the “experiences” in manufacturing quickly and accurately, giving a company the collective knowledge of potentially millions of workers and execution points in a short period of time.

For companies like Potomac, ML can provide improvements in production processes through several paths.

Predictive Maintenance

Being able to predict the future was formerly intuitive and experiential, often depending upon just a handful of human experiences. Today, using statistical analysis methodologies and techniques, large data sets from our factory floor can model events such as when machines will fail. Obviously, this knowledge has enabled Potomac to put in place systems to predict and deal with future outcomes before they happen.

Unplanned failures are the nightmare of all manufacturing lines, shutting down production and delaying order deliveries. By adding predictive analytics tools, we are able to maintain a high probability of on-time delivery for our customers’ critical parts.

Quality Control

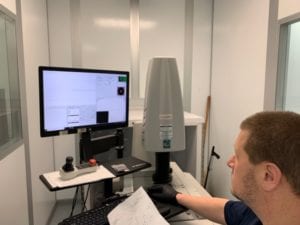

While fast turnaround times are important to Potomac’s customers, parts must simultaneously meet demanding specifications. This is especially true when fabricating at small spatial scales for applications in microfluidics and medical devices.Root Cause Analysis (RCA) is a more powerful tool when ML is added to manual RCA procedures in order to identify patterns from much larger data sets. “Big Data” then is more accurate and entirely data-driven which eliminates human bias.

Automation in Potomac’s quality control systems ensure that our customers parts are of the highest quality and meet spec every time.

Supply Chain Management

As we learned during Covid, disruptions in supply chains can totally shut down manufacturing production. ML algorithms can also be used to quickly review large amounts of data about shipping patterns, inventory, and customer trends to anticipate disruptions and institute alternative solutions to keep production flowing.

At Potomac, on-time delivery of our customers’ critical parts with high quality is paramount. Machine Learning is just one tool we use to lead the industry in high volume manufacturing for biotech, microfluidic, aerospace, automotive, and consumer products.