At year-end, Potomac enjoys reflecting back on some of the challenging applications we helped our customers in biotech, medical devices, microfluidics, electronics, rapid prototyping and consumer products solve. Of course, due to non-disclosure agreements we can’t talk about all the innovations we’ve helped develop, but here are a few that we think you’ll find intriguing for their impact on society.

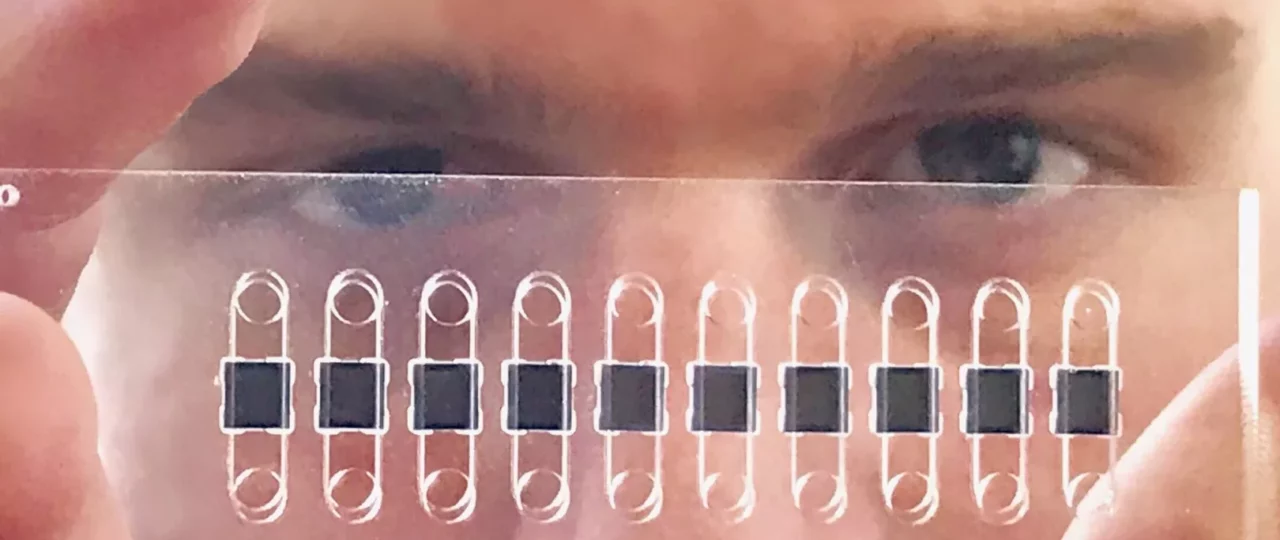

Complex Lab-on-a-Chip from Israel’s Technion Tests Antibiotic Susceptibility to Fight Coming Infection Health Crises

With antibiotic resistance becoming a global health crisis, antibiotic susceptibility in patients needs to be determined at a much faster pace in order to deliver the correct medication for a patient’s specific infection. Working with The Israel Institute of Technology [Technion] Potomac rapid prototyped a Lab-on-a-Chip that will be capable of providing results within 2 hours. The small 25 mm x 75 mm microfluidic device required Potomac’s expertise in laser and micro-CNC machining, bonding, and integration of sensors at demanding tolerances and accuracy to produce a prototype that was economical yet showed efficacy. The prototype has won a Discovery Award Grant and we expect great results in the near future. With the potential impact this product can have on world health, the prototyping project is one of the more fascinating stories on our website.

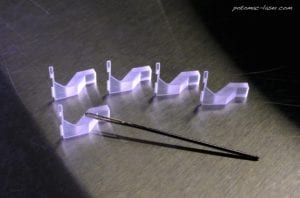

3D Printing Micro Fixture Prototypes for Cardiovascular Biomechanics Research at the University of Texas, Austin

The expense and time required for animal trials is opening a substantial market for 3D Printing alternatives. Simulation of biomechanical function for example can help researchers develop new medical devices and treatments at less cost and with reduced time to market. The University of Texas, Austin Center for Cardiovascular Simulation [CCS] is working on new research that can provide patient-specific modeling. “Potomac was the first 3D Printing company I contacted that could handle the small spatial scales I needed”, explains John Lesicko, a staff member at CCS. “Plus they could deliver at a reasonable price.” You can read the full story here and learn how Potomac’s 3D Printing is expediting medical research that will potentially improve treatment for anyone with cardiovascular disease.

Getting Capital One Personalized Credit Card Prototypes to SXSW

One of the cooler applications Potomac undertook this past year was laser marking credit cards in exotic and beautiful materials for Capital One. From copper to seashells and skateboard material to wood, not only can bank customers have their signatures engraved on their cards, the substrates can also be unique. With the wide range of laser wavelengths we have in-house, Potomac can cut or mark just about any material so it was technically an easy job for us. But in this case Capital One needed the prototypes for a big demo at the hip SXSW conference in Austin, Texas happening in just a few days. Our customer service team jumped into action and made the deadline, saving Capital One from having an empty display for the new Project Elements. You can see photos of the cool credit cards in the full story.

While these are just a few of the many applications Potomac has helped our customers bring to life, we hope they give you a glimpse of the impactful work we do every day. While we love advanced manufacturing, it is gratifying to be in a field where we can also help others, especially our medical research partners. We are looking ahead and will continue changing the world in 2018. Happy New Year from all of us at Potomac!