Potomac has developed unique laser processing capabilities, especially of thin glass, that has special application for bioscience research. Two recent projects reported in Nature | Methods and the Journal of Neuroscience required laser cutting tiny features in thin glass coverslips with minimal cracking or damage to the substrate. Here are details about the research that used our manufacturing techniques:

From Nature | Methods

A group of researchers from Cornell University, the Baylor College of Medicine, and Rice University have developed a high-resolution optical imaging technique that is critical to understanding brain function. The novel method allows for noninvasive recording of neuronal activity with high spatial and temporal resolution deep within brain tissues. The paper, In vivo three-photon imaging of activity of GCaMP6-labeled neurons deep in intact mouse brain, describes the process for capturing images in live mice.

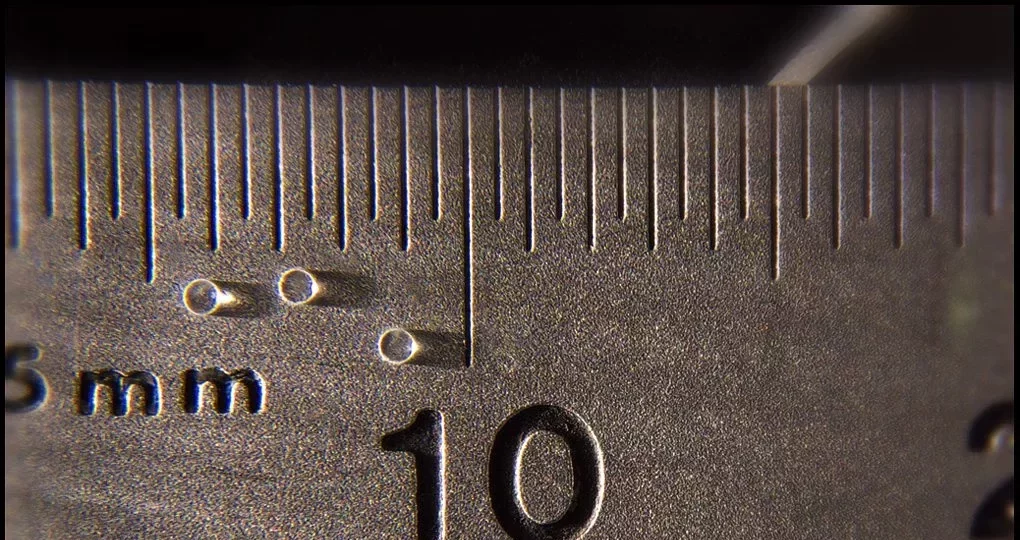

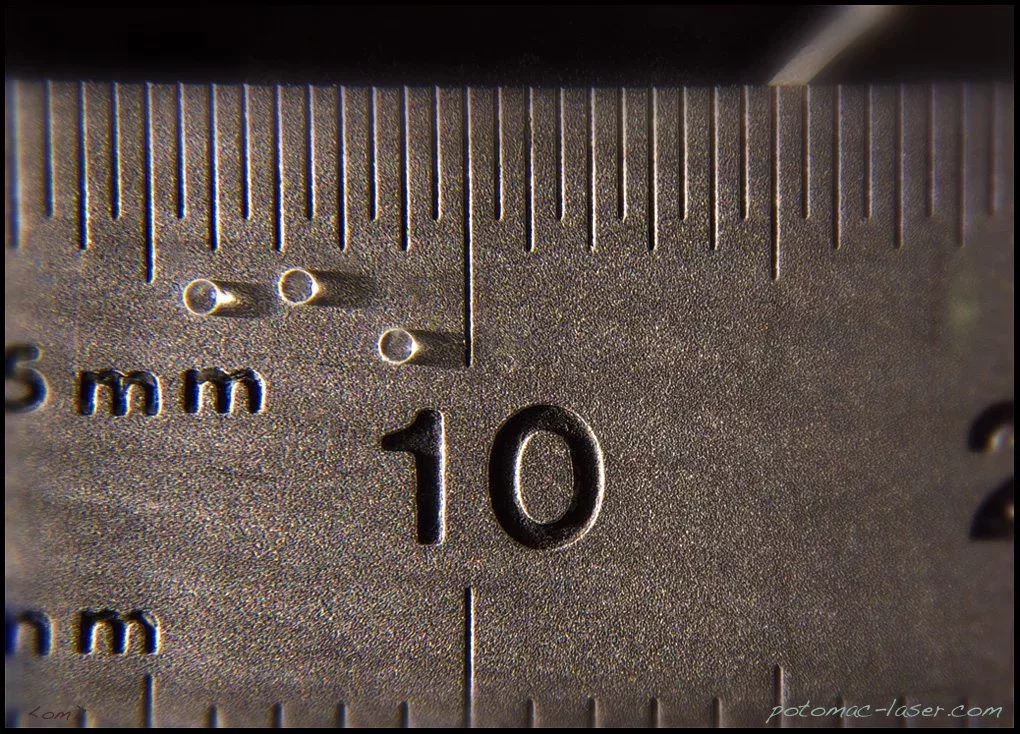

Reducing the potential for tissue growth under the imaging window required a coverslip assembly. Laser micro-machined by Potomac in thin glass, the donut-shaped coverslip has an inner diameter of 4.5 mm with an outer diameter of 5.5 mm. Precision in the size and placement was important since the coverslip needed to fit snugly into the open mouse cranial window.

From the Journal of Neuroscience

Research generated in the Department of Neurobiology at Northwestern University looks at the impact sensory deprivation has on normal development of neural networks. Results in the paper, Environmental Enrichment Rescues Binocular Matching of Orientation Preference in the Mouse Visual Cortex, also involves imaging in live mice. The experiment required implantation of a glass window made up of two layers of glass: a lower glass slide and a 4.0 mm coverslip with a 2 mm diameter hole which Potomac was able to laser micromachine into the center.

Laser Micromachining Glass

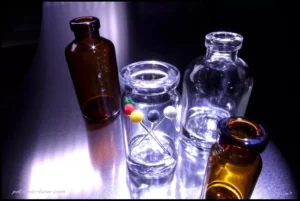

There are many types of glass but the commonality is that these versatile materials are hard and brittle solids. Those same properties that make glass a desirable material for many applications also make it difficult to machine. Working closely with our customers, Potomac has developed specialized techniques to machine glass without damage or cracking, especially when working with very thin glass which is needed for biotech and medical device applications. We have a wide variety of tools in our facility to machine complex features in glass as small as 1 micron. In addition to cutting holes in thin cover slips, Potomac has extensive experience drilling holes for leak testing of pharmaceutical vials and ampoules, creating microfluidic devices and drilling through holes for microelectronic and sensor applications.

To learn more about processing glass at Potomac, check out the Glass page in the Services section on our website!