Advanced research in basic science is continually pushing the limits of commercially available chemical analysis equipment. Such is the case for the Kong group at Oregon State University whose physical chemistry work involves studying the basic structure of materials on the atomic level.

Dr. Wei Kong has been actively designing new tools that are important to other researchers worldwide in these new fields. Part of the design involves Kapton gaskets that are being used in a cryogenic pulsed valve that operates at temperatures lower than 20 K and pressures over 20 atm. The purpose of the valve is to generate superfluid helium droplets for doping with a variety of molecules and ions. Properties of the dopant can then be studied in the non-interacting gentle environment of helium at temperatures near absolute zero degrees Kelvin.

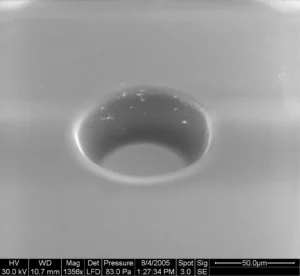

Dr. Wei explains the complexity of her design: “The orifice of 50 micron in diameter is the size of the opening when the pulsed valve is powered on for gas release. The operating conditions require extreme thermal and mechanical stability. The wear and tear of the repetitive motion of the driving mechanism, along with the contaminations of condensed impurities on the surface of the gasket due to its low operational temperature make the gasket a consumable component.”

Dr. Wei’s quest for mechanically fabricating the gaskets led to laser micromachining. She explains that, “many machinists told me that is was not possible to mechanically make a part with the size and accuracy we needed for our design. So we turned to laser machining due to the small spatial scale – 50 micron diameter holes – and the ability to have good cut quality in our material.”

Potomac was uniquely suited to help Dr. Wei. With the ability to create holes as small as 1 micron, Potomac UV laser micromachining capability more than met her needs. Organic polymers are especially conducive to the photoablative material removal process of uv lasers, which minimizes thermal damage or heat affected zone.

Consumable components also must be economically viable for the long-term operation of new equipment. Over the years, Potomac has been able to optimize laser micromachining to create the most affordable parts on the market.

Many scientific breakthroughs and discoveries are dependent on a fundamental understanding of materials. Work like that being carried on at Oregon State will have far-reaching effects in many fields beyond physical chemistry. We, at Potomac, are excited to contribute to the future of many exciting discoveries.