Oct. 24, 2013, Laser micromachining company, Potomac Photonics, is pleased to announce the addition of another Coherent UV laser to its micromanufacturing unit. This laser will be optimized for laser micromachining applications, such as leak test hole drilling, probe card hole drilling, precision marking, and excision of complex polymer parts.

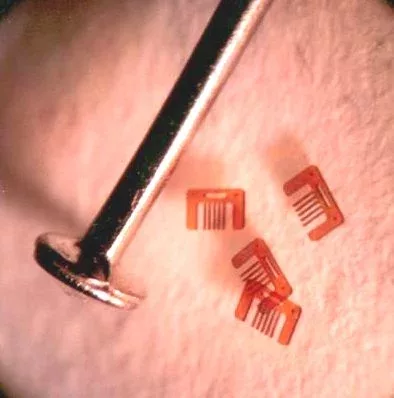

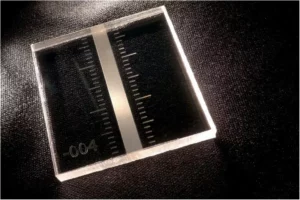

Materials such as polyimide, PEEK, polystyrene, nylon polycarbonate, Teflon, glass, and Ultem can be machined with features as small as 1 micron.

UV laser micromachining can be a very effective process for rapid prototyping to production of miniature parts. The cut quality for high absorption materials can be extremely clean and non-thermal due to the ability of the laser to disrupt the molecular bonds via a process called ablation. This characteristic is important for customers who want to minimize debris and limit secondary cleaning processes that can often be both costly and time consuming.

A drawing such as a .dxf file or .pdf is all that is required for customers to have their parts fabricated quickly and cost-effectively.

“This laser will address our growing demand in areas such as laser cutting and hole drilling for prototyping and production applications,” stated Sidney Wright, Vice President of Sales, Potomac Photonics.

For over 30 years, Potomac Photonics has been a leader in digital fabrication, working in advanced technologies such as laser micromachining, 3D Printing, laser marking, hot embossing and micro-CNC. Potomac’s contract services span prototyping to production, helping clients develop miniature products and bring them to market. Potomac has been recognized by both commercial and government agencies for innovation in areas such as medical device, electronics, aerospace, and automotive manufacturing. Potomac’s high-tech facility, located in Lanham, MD, is ISO 9001:2008 and ISO 13485:2003 certified. Please visit the website at http://www.potomac-laser.com