Laser marking Creates Remembrance for Marine Corp Veteran

Potomac has had a long history working with U.S. government agencies over the years. Our first R&D funding came from the Small Business Innovation Research program that supported our UV laser and Laser micromachining development with grants from DARPA, the Air Force Office of Scientific Research, the Naval Research Laboratory, NASA, the National Science Foundation and the National Institutes of Health. But we have always had a special relationship with the services. Our founder, Paul Christensen’s dad was a bomber instructor in World War II and current President and CEO Mike Adelstein also served our country early in his career. In our long history, we’ve also hired a number of veterans

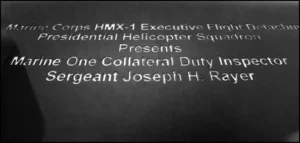

So it was natural that we would contribute some laser expertise to a project that honored a Marine who is retiring. Joe Rayer is a Collateral Duty Inspector for helicopters, a job he clearly has enjoyed! Joe’s role is to oversee aircraft before they go out to fly from the Quantico base in Virginia. He is retiring from the Marine Corps and he and his team wanted to create something by which he could remember his years in the Corps.

Like a lot of air bases, Quantico has spare parts, many from out of service aircraft and Joe’s unit had a piece of an old H-3 helicopter’s main rotor blade. This general workhorse aircraft designed by the Sikorsky division of United Technologies had its first flight in 1959 and went into production in 1961. While the H-3 had a long career, it has since been replaced by more modern technology.

Joe wanted to have his unit’s emblem laser etched through the paint on the H-3’s aluminum rotor blade so he conducted an Internet search and Potomac’s skill set matched his laser marking needs. At the correct wavelength, lasers can remove paint without burning through the substrate material or etch directly into a material without cutting all the way through the part.

Joe reports that the “Potomac work was outstanding!” But he was especially impressed by the sincerity and generosity of the company. Joe expands his appreciation to say, “Potomac really operates like a family and cared about my project as if I was a big customer!” Potomac’s Mike Adelstein reiterates “Potomac values the sacrifices made by our men and women in uniform and wanted to do as much as we could to help. We were happy to donate the laser marking for Joe’s commemorative piece. He deserved it!”

Joe now has a piece of helicopter history that he says is something he hopes to pass down through the generations as a memory of his service to his country. We are only happy that we could help in a small way to make that hope into a reality.