One of the key characteristics of a true Digital Fabrication expert group is the ability to go beyond 3D Printing, cutting, or drilling to meet the total needs of our customers. And at Potomac we try to do just that.

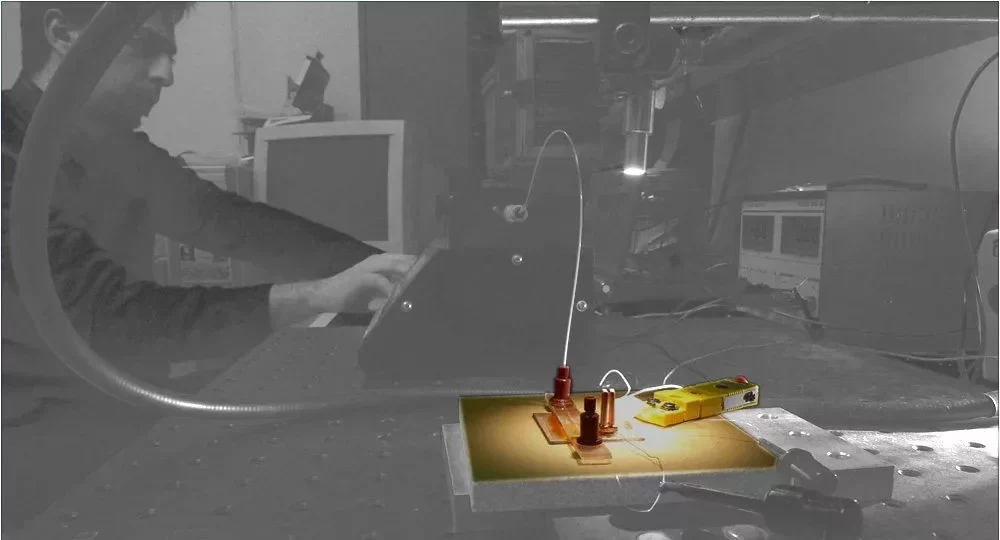

In our work with microfluidic devices, Potomac saw a need for better control of the devices’ performance. So, to serve our customers, we initiated a joint R&D project with the Mechanical Engineering Department at the University of Maryland, Baltimore County where we are now located in the bwtech@UMBC R&D Technology Park.

Collaborating with Professor Tony Farquhar and Ph.D. student Amir Harandi and PotomacMeso’s Dr. Paul Christensen, we’ve generated early results that give our customers a quicker, easier, less expensive tool for monitoring and controlling flow in these small “Lab on a Chip” structures.

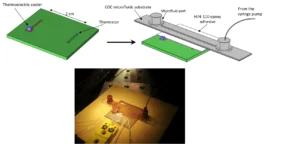

The current state of the art for most applications is to use very fine metal patterns with depths as small as 1/5 of a micron to monitor temperature changes or as heaters in or near the microfluidic channel. However, due to their small size, these structures are produced with photolithographic processes that require multiple, time-consuming steps and are also cost and labor intensive. The tiny size means they are also difficult to manipulate, and accurate placement on the production level is challenging.

In the first stages of this R&D Project, Potomac and UMBC used our microfabrication technology to place self-heated thermistors of sub-millimeter size near a flow channel in a way that can lead to improved flow monitoring. In addition to the rapid prototyping potential of the heated thermistor, its resistance is also more sensitive to temperature so we were able to get a stronger electrical signal. It is also less expensive to produce and can be integrated easily with standard surface mount technology.

Dr. Christensen credits UMBC’s excellent modeling capabilities in the quick results we were able to achieve. He points out: “Dr. Farquhar’s group has extensive experience modeling temperatures of complex structures. That allowed us to optimize the parameters of the heated thermistors quickly and easily.”

Dr. Christensen credits UMBC’s excellent modeling capabilities in the quick results we were able to achieve. He points out: “Dr. Farquhar’s group has extensive experience modeling temperatures of complex structures. That allowed us to optimize the parameters of the heated thermistors quickly and easily.”

Watch this space for updates on other ways in which we are giving our customers complete solutions to their tough manufacturing problems.