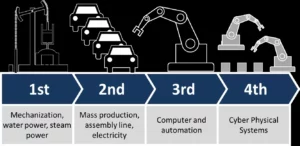

For the past few decades, we’ve been living in the Third Industrial Revolution where advanced manufacturing meant production utilizing computers and automation. CAD-driven machine tools, robots and lasers were the order of the day.

In recent years, Industry 4.0 has come on the manufacturing scene. What does this change mean and how does it impact the fabrication of your parts and products?

Factory As A System

The integration of computers, machine tools and automation with new technologies like the Internet of Things, sensors, feedback loops and real-time analytics tie the parts of the factory into a single system that functions in unity. A single Digital Thread winds through the entire system from CAD design and simulation to production of products. This same link moves up and down the supply chain, fully inter-connecting suppliers and even customers with the factory.

The integration of computers, machine tools and automation with new technologies like the Internet of Things, sensors, feedback loops and real-time analytics tie the parts of the factory into a single system that functions in unity. A single Digital Thread winds through the entire system from CAD design and simulation to production of products. This same link moves up and down the supply chain, fully inter-connecting suppliers and even customers with the factory.

As you can imagine, the factory that is a manufacturing system operates at higher efficiencies. Feedback loops of Big Data generated in production can be used by artificial intelligence and machine learning to improve processes. Information can also be gathered and analyzed by factory workers. These tools help management make a wide range of operational decisions that are not executed in a vacuum from factory floor experience.

Simple Feedback Loop Between Data & Plant Floor

Simple Feedback Loop Between Data & Plant Floor

60 industrial experts who were interviewed for a white paper by Siemens, the digital transformation platform company, say they saw between 6.3 and 10 percent gains in productivity through the implementation of digital technology that links elements of the factory and their supply chain. The more that a manufacturer, especially in high volume production like we face at Potomac, can increase efficiency, the higher quality the output for customers, often at reduced prices.

Predictive Analytics

Manufacturers hate surprises, and none more so that when equipment goes down in the midst of production runs. Predictive analytics allows us to take historical data generated on the factory floor and model scenarios that predict future occurrences. Being able to schedule maintenance, replace equipment parts or add upgrades in advance of failures ensures that production just about never stops.

At Potomac, on-time delivery is one of our hallmarks and we pride ourselves on doing all in our power to meet customer lead-times. The use of data to stay on top of our equipment’s health is key to this customer benefit.

Impact on Digital Fabrication

Basically for manufacturing customers, Industry 4.0 and its ability to turn a factory into a fully integrated system of technologies translates into higher quality parts, produced within short turnaround times, at ever decreasing costs.

Potomac is continually looking to improve our customer experience and implementing Industry 4.0 concepts is just one of our efforts to advance manufacturing practices into the 21st century.